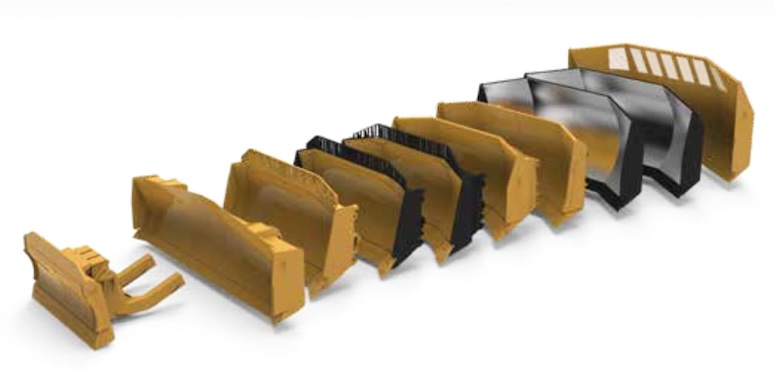

- Different Types of Dozer Blades

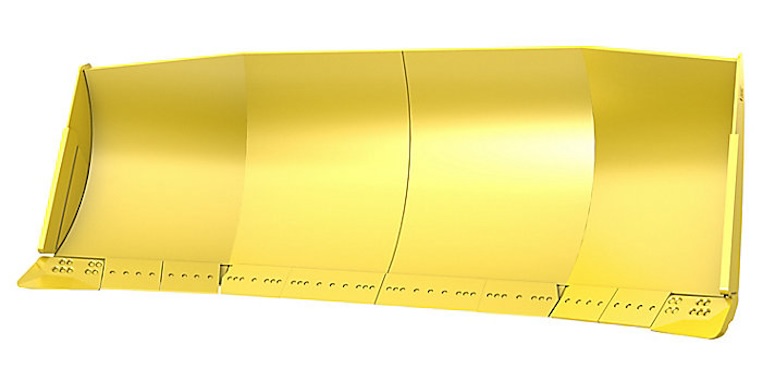

- S Blade (Dozer Straight Blades)

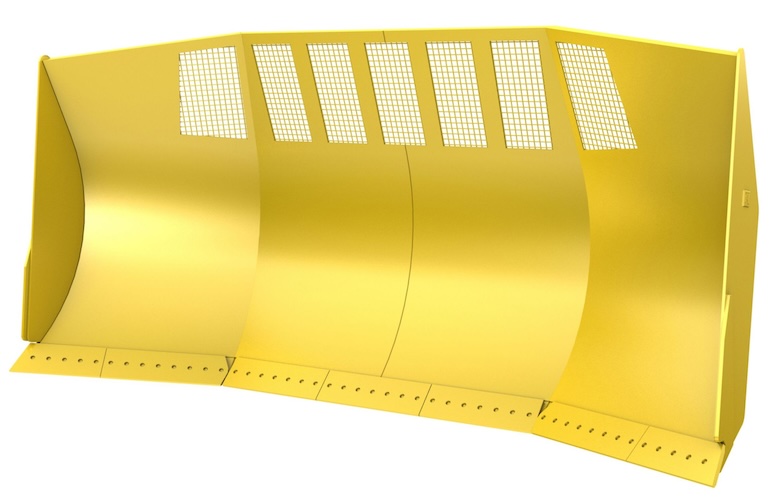

- U Blade (Dozer Universal Blades)

- Coal U-Blades

- Landfill U-Blades

- Reclamation U-Blades

- Woodchip U-Blades

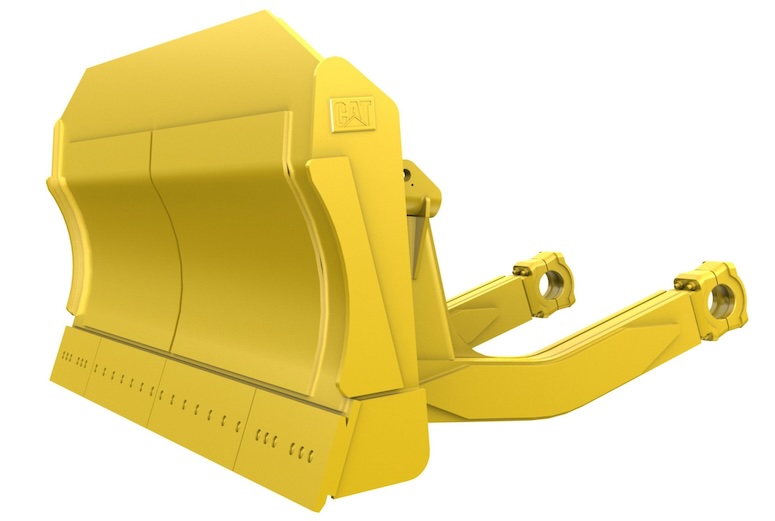

- SU Blade (Dozer Semi-Universal Blades)

- A Blade (Dozer Angle Blades)

- PAT Blade (Dozer Power Angle Tilt Blades)

- VPAT Blade (Dozer Variable Pitch Power Angle Tilt Blades)

- CU Blade (Dozer Cushion Blades)

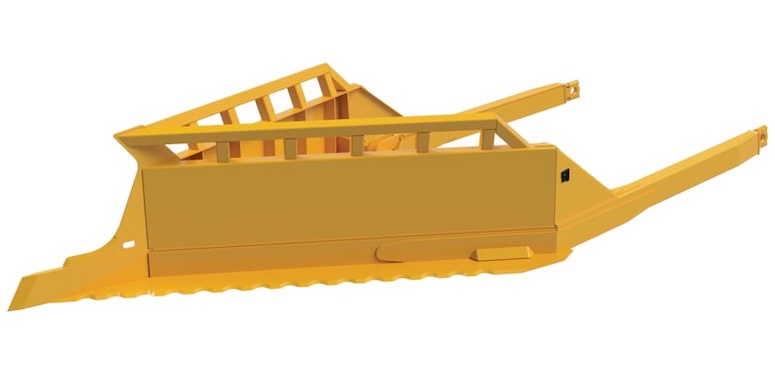

- V Blade (V-shaped Clearing Blades)

- How to Select the Right Dozer Blade?

A dozer blade, also known as a bulldozer blade, is an attachment mounted to the front of a craweler or wheel bulldozer or other heavy equipment machinery. It is used for various earthmoving and construction tasks, such as pushing, grading, leveling, and moving materials like soil, rocks, and debris. Dozer blades come in different sizes, shapes, and configurations to suit different applications and site conditions. Common types of dozer blades include straight, angle, univelral, & semi-univelral. Each type has its own advantages and is designed for specific tasks and terrain conditions.

These blades are typically made of durable materials like hardened steel and are equipped with features such as hydraulic controls for adjusting blade angle, tilt, and height. Some blades may also have additional features like cutting edges, ripper teeth, or wings for increased versatility and functionality. Overall, a dozer blade is a versatile and essential attachment for bulldozers and other heavy equipment, allowing operators to efficiently and effectively perform various earthmoving and grading tasks on construction sites, mining operations, and other worksites.

Different Types of Dozer Blades

In construction, mining, landscaping, & waste Industry, various types of dozer blades are employed to meet specific requirements and challenges. Here are some common types:

| Dozer Blade Type | Best Results with | Description | Manufacturers |

|---|---|---|---|

| Straight Blade (S Blade) | General earthmoving tasks | designed for basic earthmoving tasks such as grading, leveling, and pushing material. | Caterpillar, Komatsu, John Deere, Dymax, Enstruc, Paladin Attachments |

| Universal Blades (U Blade) | Various terrains and materials | suitable for a wide range of applications, including coal mining, landfill operations, reclamation projects, and woodchip handling. | Caterpillar, Komatsu, Liebherr, Craig, Kenco, Paladin Attachments, Enstruc, Bedrock Attachments |

| – Coal U-Blades | Coal mining operations | designed for handling coal and overburden materials in coal mining environments. | Caterpillar, Komatsu, Liebherr, Dymax, Rockland, Weldco-Beales, Enstruc |

| – Landfill U-Blades | Landfill operations | optimized for use in landfill sites, capable of handling diverse materials and providing efficient compaction. | Caterpillar, Dymax, Komatsu, Rockland, Liebherr, Craig, Enstruc |

| – Reclamation U-Blades | Land reclamation projects | engineered for land reclamation projects, offering enhanced control and precision in reshaping terrain. | Caterpillar, Komatsu, Liebherr, Rockland, Dymax, Enstruc |

| – Woodchip U-Blades | Woodchip handling | designed for handling woodchips and other forestry materials, featuring high sides for containment and control. | Caterpillar, Dymax, Komatsu, Liebherr, Rockland, Kenco, Craig, Weldco-Beales |

| Semi-Universal Blades (SU) | Varied applications | offering versatility for a range of tasks, combining features of both universal and straight blades. | Caterpillar, Komatsu, Liebherr, Dymax, Paladin Attachments, Rockland, Enstruc, Bedrock Attachments |

| Angle Blades (A Blade) | Trenching and backfilling | with adjustable angle capabilities, ideal for trenching, backfilling, and shaping ditches and embankments. | Caterpillar, Komatsu, Dymax, Paladin Attachments, Liebherr, Rockland, Kenco, Weldco-Beales |

| Power Angle Tilt Blades (6-Way PAT) | Precision grading and shaping | equipped with power angle and tilt functions for precise grading, shaping, and contouring of terrain. | Caterpillar, John Deere, Komatsu, Liebherr, Weldco-Beales, Enstruc, Kenco |

| Variable Pitch Power Angle Tilt Blades (VPAT) | Versatile grading and shaping | with variable pitch technology, offering enhanced versatility and control for grading and shaping tasks. | Caterpillar, Komatsu, Liebherr |

| Cushion Blades (CU Blade) | Rough terrain and uneven ground | featuring cushioning mechanisms to absorb impact and reduce stress on the machine and operator in rough terrain. | Caterpillar, Komatsu, Liebherr |

| Clearing Blades (V-shaped Blade) | Clearing snow, soil, debris, or other loose materials | features a V-shaped design that efficiently directs material away from the center, reducing resistance and allowing for smoother operation. Typically equipped with adjustable wings or side plates for versatile clearing width options | Rockland, Marden Industries, Savannah Global Solutions |

S Blade (Dozer Straight Blades)

The most basic type of dozer blade, suitable for general-purpose pushing and leveling. Dozer Straight Blades are essential attachments that significantly enhance the versatility and efficiency of bulldozers across various industries. These S-blades are designed to perform a wide range of tasks, from grading and leveling to pushing and spreading materials.

With their robust construction and precise engineering, Dozer S Blades offer exceptional durability and performance in demanding work environments. They are indispensable tools for construction sites, mining operations, agriculture, and land development projects.

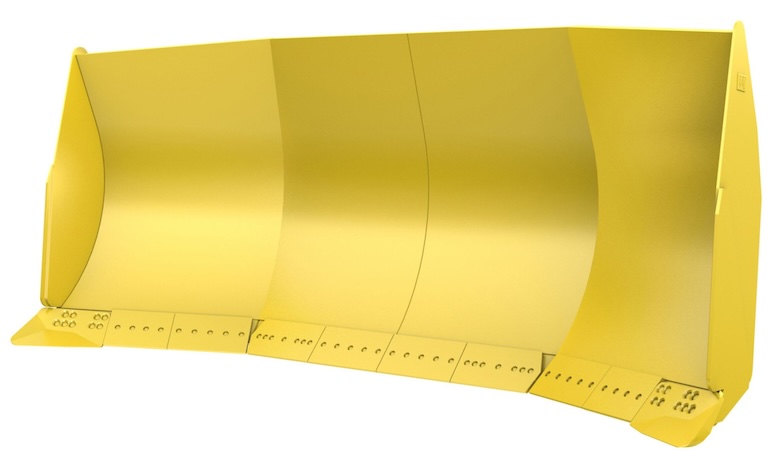

U Blade (Dozer Universal Blades)

Dozer Universal Blades, commonly referred to as U Blades, are versatile attachments designed to enhance the functionality of bulldozers in various applications. Each type is engineered with specific features to cater to the unique requirements of different industries and environments.

These U-Blades are instrumental in maximizing the productivity and efficiency of bulldozers across diverse sectors, ranging from mining and construction to waste management and environmental restoration. Let’s explore the characteristics and applications of each type of U Blade in detail.

Coal U-Blades

Coal U-Blades are specialized attachments designed for bulldozers used in coal mining operations. These heavy-duty blades are specifically engineered to handle the unique challenges and demands of coal mining environments, where efficient material handling and precise grading are essential for productivity and safety. The primary function of Coal U-Blades is to facilitate the movement, loading, and grading of coal and overburden materials in coal mining sites. These blades are characterized by their robust construction, large capacity, and high sides, allowing them to effectively contain and move large volumes of coal and other materials across mining sites.

Coal U-Blades are equipped with specialized features tailored to the requirements of coal mining operations. They often feature reinforced cutting edges, heavy-duty construction materials, and abrasion-resistant components to withstand the abrasive nature of coal and mining debris, ensuring long-term durability and performance in demanding mining environments.

Landfill U-Blades

Landfill U-Blades are specialized attachments designed for bulldozers used in landfill operations and waste management applications. These blades play a crucial role in managing waste materials, shaping landfill cells, and maintaining the integrity of landfill infrastructure. The primary function of Landfill Blades is to efficiently compact and spread waste materials within landfill cells, ensuring optimal space utilization and waste containment. These blades feature a robust design optimized for handling various types of waste, including municipal solid waste, construction debris, and industrial by-products, making them essential tools for landfill operators and waste management professionals.

Overall, Landfill U-Blades are essential tools for landfill operations and waste management activities, offering unmatched efficiency, versatility, and durability for compacting waste materials and maintaining landfill infrastructure. With their specialized design and advanced features, Landfill U-Blades play a vital role in promoting efficient waste disposal practices and ensuring the safe and sustainable management of landfills.

Reclamation U-Blades

Reclamation U-Blades are specialized attachments designed for bulldozers used in land reclamation and environmental restoration projects. These blades play a crucial role in reclaiming disturbed land, restoring natural habitats, and rehabilitating sites affected by mining, construction, or other industrial activities.

One of the key characteristics of Reclamation U-Blades is their large capacity and high sides, which allow them to contain and move substantial amounts of material efficiently. These attachments are typically wider and taller than standard bulldozer blades, enabling them to cover larger areas and achieve greater productivity in reclamation projects.

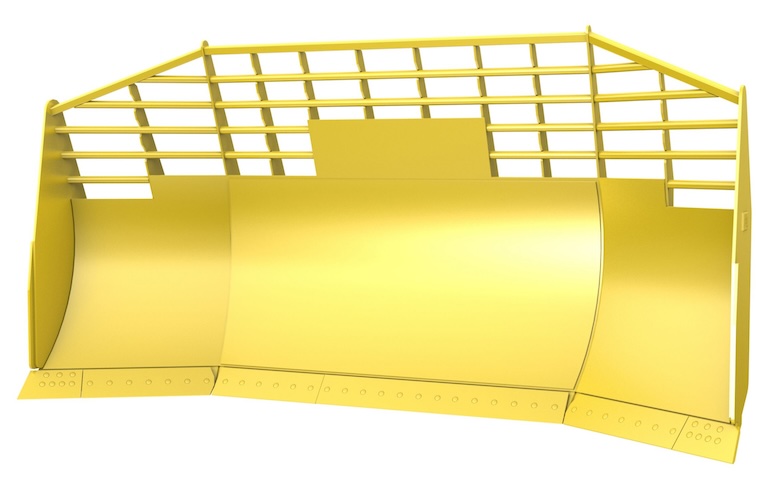

Woodchip U-Blades

Woodchip U-Blades are specialized attachments designed for bulldozers used in forestry and land-clearing applications, where efficient handling and processing of wood materials are essential. These blades feature a unique design optimized for pushing, loading, and spreading woodchips, brush, and other organic debris, making them indispensable tools for forestry operations, land reclamation projects, and site preparation tasks in wooded areas.

The key characteristic of Woodchip U-Blades is their high-capacity design, which allows them to handle large volumes of wood materials with ease. These blades typically have a wide profile and high sides to contain and transport bulky wood debris efficiently, minimizing spillage and maximizing productivity on the job site.

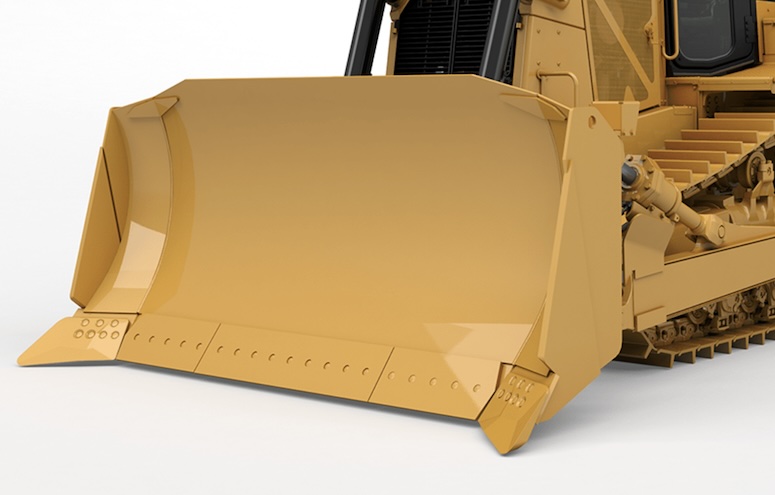

SU Blade (Dozer Semi-Universal Blades)

Dozer Semi-Universal Blades are versatile attachments designed to provide superior performance and flexibility in a variety of earthmoving and construction applications. These attachments combine the functionality of both straight and U blades, offering a balance between precision and versatility.

With their adjustable wings, Dozer Semi-Universal Blades allow operators to customize the attachment configuration to suit specific job requirements. Whether it’s grading, backfilling, or spreading materials, these blades excel in a wide range of tasks, making them invaluable tools on construction sites, mining operations, and agricultural projects.

A Blade (Dozer Angle Blades)

Dozer Angle Blades are essential attachments widely used in the construction, landscaping, and agricultural industries for pushing, leveling, and grading tasks. These versatile blades feature a unique design that allows them to tilt and angle, providing enhanced maneuverability and precision during operation.

Ideal for shaping slopes, ditches, and embankments, A-Blades offer operators the flexibility to adjust the blade angle to accommodate different terrain contours and project requirements. Whether it’s clearing snow, spreading materials, or creating drainage channels, these blades excel in a variety of applications, making them indispensable tools on job sites.

PAT Blade (Dozer Power Angle Tilt Blades)

Dozer PAT Blades (Power Angle Tilt), are advanced attachments designed to enhance the capabilities and versatility of bulldozers and other heavy equipment. These specialized attachments offer operators the ability to precisely adjust the angle, tilt, and pitch of the blade, providing unmatched control and efficiency in various earthmoving and grading applications.

Equipped with hydraulic systems, PAT Blades allow operators to effortlessly adjust the blade angle and tilt from the comfort of the cab, eliminating the need for manual adjustments and maximizing productivity on the job site. This versatility enables the blade to tackle a wide range of tasks, including leveling, grading, ditching, backfilling, and shaping terrain with precision and accuracy. PAT are commonly used in construction, mining, road building, agriculture, and land development projects, where their ability to adapt to changing terrain conditions and tackle complex grading tasks makes them indispensable tools.

VPAT Blade (Dozer Variable Pitch Power Angle Tilt Blades)

VPAT Blades (Variable Pitch Power Angle Tilt) represent the pinnacle of versatility and precision in bulldozer attachments. These advanced attachments feature a range of innovative technologies that allow operators to adjust the blade’s pitch, angle, and tilt with exceptional precision, enabling them to tackle a wide variety of grading, shaping, and leveling tasks with ease.

VPAT Blades are equipped with advanced hydraulic systems and intuitive controls that allow operators to make real-time adjustments to blade position, angle, and tilt from the comfort of the cab, enhancing operator comfort, productivity, and safety.

With their unmatched versatility and precision, VPAT are indispensable tools for modern construction and earthmoving projects, offering unparalleled performance and efficiency in a variety of operating conditions.

CU Blade (Dozer Cushion Blades)

CU Blades (Cushion), are specialized attachments designed to provide exceptional shock absorption and surface protection for bulldozers and other heavy equipment. These innovative blades feature a unique cushioning mechanism that reduces the impact force transmitted to the ground during operation, minimizing ground disturbance, and protecting delicate surfaces from damage.

The primary function of CU Blades is to mitigate the adverse effects of heavy machinery on sensitive terrain, such as asphalt, concrete, and other paved surfaces. By dispersing the energy generated by the blade’s movement, Cu-Blades help minimize soil compaction, surface deformation, and rutting, preserving the integrity of the underlying terrain and reducing the need for costly repairs and restoration in a variety of industries, including construction, landscaping, road maintenance, and environmental conservation.

V Blade (V-shaped Clearing Blades)

V Blades for Dozer, also known as V-shaped Clearing Blades, represent a revolutionary advancement in land-clearing technology. These specialized attachments are designed to tackle a wide range of challenging terrain and environmental conditions with unparalleled efficiency and precision. By harnessing the power of a V-shaped design, these blades excel in pushing and clearing snow, soil, debris, and other materials with minimal resistance.

Many V Blades are equipped with adjustable angles, allowing operators to customize the blade’s position for optimal performance and versatility. Some models feature reversible cutting edges, extending the blade’s lifespan and reducing maintenance requirements. Clearing Blades are designed to be compatible with a wide range of dozer models, ensuring seamless integration and compatibility with existing equipment.

Each type of dozer blade offers unique advantages and is selected based on factors such as the nature of the material being handled, the terrain, and the specific requirements of the job at hand.

How to Select the Right Dozer Blade?

Selecting the right dozer blade involves considering various factors to ensure optimal performance and efficiency. Here’s how to approach the selection process:

- Size of Dozer:

- Choose a dozer blade size that is compatible with the size and power of your equipment.

- Larger dozers can typically handle larger and more robust blades for increased productivity and efficiency.

- Types of Materials You’re Moving:

- Consider the type of material you’ll be working with, whether it’s loose soil, rocks, gravel, or other debris.

- Select a blade design and configuration that is well-suited for the specific material conditions, such as a coal blade for loose materials or a straight blade for general-purpose grading.

- Applications You Expect to Work In:

- Evaluate the range of tasks and applications you expect to perform with the dozer blade, such as grading, pushing, leveling, or loading.

- Choose an attachments type that offers the versatility and functionality required for your intended applications, such as an angle blade for precise grading or a U-blade for heavy material handling.

- Terrain, Underfoot Conditions, & Site Conditions:

- Assess the terrain and underfoot conditions of your work site, including factors like slope, soil type, and obstacles.

- Select an attachments with features suited to the site conditions, such as a cushion blade for rough terrain or a power angle tilt blade for uneven surfaces.

- Productivity, Cost, & Utilization Goals:

- Consider your productivity, cost, and utilization goals when choosing a dozer blade.

- Balance factors such as blade size, design complexity, and additional features with your budget and performance expectations to maximize ROI.

- Consult with Experts:

- Consult with equipment dealers, manufacturers, or industry experts to get recommendations tailored to your specific requirements.

- Take advantage of their expertise and experience to ensure you choose the right dozer blade for your needs.

By carefully evaluating these factors and consulting with experts as needed, you can select a dozer blade that enhances productivity, minimizes costs, and meets your operational objectives effectively.

The VPAT blade is my favorite! With this attachment, your bulldozer can do everything on the ground!

Yes, today Six-Way PAT is the most high-tech blades for bulldozers, capable of precision work on different soils and for different tasks!

What is the difference between U blade and SU blade?

The main difference between a U blade and an SU blade lies in their design and versatility! U blades are universal attachment that offer versatility in various applications, such as mining, reclamation, landfill, and woodchip handling. They typically feature a curved shape resembling the letter “U,” allowing for efficient material gathering and handling. U blades are suitable for a wide range of tasks but may not offer the same level of specialization as other types. Semi-Universal blades, are a variation of U blades designed to provide enhanced versatility and performance. They retain the curved shape of U blades but often feature additional design elements for improved functionality. SU blades may incorporate features such as a taller profile, extended wings, or reinforced structure, allowing for better material containment and increased productivity – ideal for applications requiring a balance between versatility and specialized performance, offering enhanced capabilities compared to standard U blades.