The production of blades for bulldozers is a crucial aspect of heavy equipment manufacturing. These dozer blades are typically manufactured using high-quality steel and advanced fabrication techniques to ensure durability and efficiency in various applications. One of the most challenging aspects of making bulldozer blades is ensuring their durability and longevity under extreme working conditions. Bulldozer blades are subjected to significant wear and tear due to their constant exposure to abrasive materials, heavy loads, and harsh environments. To address this challenge, manufacturers must carefully select high-quality materials and employ advanced manufacturing techniques to enhance the blade’s strength and resistance to abrasion, impact, and fatigue.

Optimizing the design and geometry of the blade to distribute stress evenly and minimize weak points is crucial for improving its overall durability. Furthermore, achieving precision in fabrication processes such as cutting, bending, and welding is essential to ensure the blade’s structural integrity and performance. Any deviations or imperfections in these processes can compromise the blade’s strength and longevity, leading to premature failure and increased maintenance costs for the end-user.

TOP Bulldozer Blade Manufacturers & Suppliers in USA

Overall, balancing the requirements for strength, durability, and performance while also considering factors such as cost-effectiveness and manufacturability poses a significant challenge in the production of bulldozer blades. Effective collaboration between engineers, designers, and manufacturing teams is essential to overcome these challenges and deliver high-quality blades that meet the demanding requirements of the construction and mining industries. Here’s a list of bulldozer blade manufacturers and suppliers in the United States:

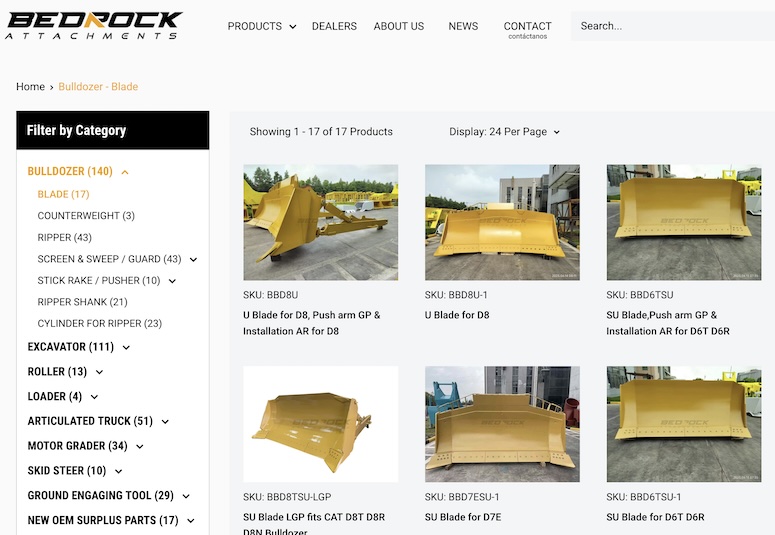

Bedrock

Established in 2011, Bedrock Attachments has undergone significant expansion, now boasting a global footprint and a workforce exceeding 400 individuals. Extensive selection of over 700 SKUs encompasses a diverse array of attachments, ranging from buckets and dozer blades to rippers, couplers, and specialized tools. Each product is meticulously designed to optimize productivity, minimize downtime, and prioritize operator safety, all while utilizing top-quality steel to ensure durability and performance, complemented by a one-year warranty.

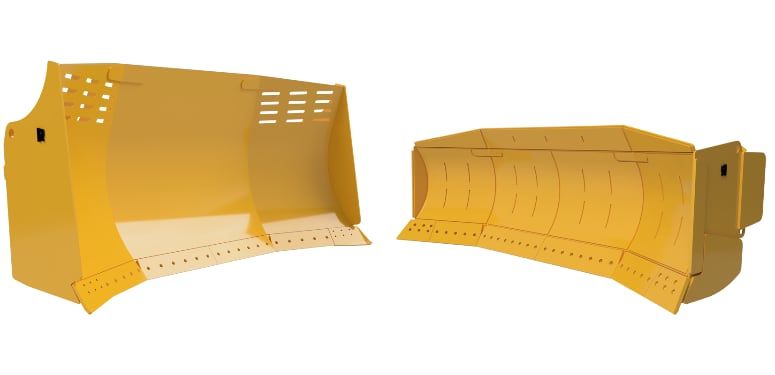

- Range of dozer blades: U-Blades, SU-Blades.

- Address: 8925 Research Drive, Irvine, CA 92618 United States.

- Official website: bedrockattachments.com

CASE CE

With a diverse portfolio encompassing 11 brands, Paladin Attachments offers an extensive array of dedicated work tools tailored to meet the unique needs of every customer, from small compact tool carriers to large dozers. At the forefront of innovation, Paladin leads the market as a manufacturer of highly engineered attachment products, including dozer blades.

- Range of dozer blades: The whole range of blades for CASE bulldozers.

- Address: 7100 Durand Ave, Sturtevant, WI 53177, United States.

- Official website: casece.com

Caterpillar

CAT, Inc., renowned for its heavy machinery and equipment, stands as a global leader in the construction, mining, agriculture, and transportation industries. With a vast array of products, including bulldozers, excavators, and generators, CAT’s commitment to innovation and quality shines through. With a robust global presence and a rich history of delivering reliable solutions, CAT continues to be a trusted name in the world of heavy equipment.

- Range of dozer blades: Straight Blades, Universal Blades (Coal / Landfill / Reclamation / Woodchip U-Blades), Semi-Universal Blades, Angle Blades, Power Angle Tilt Blades, VPAT-Blades, Cushion Blades.

- Address: 100 NE Adams St, Peoria, IL, 61629, United States.

- Official website: cat.com

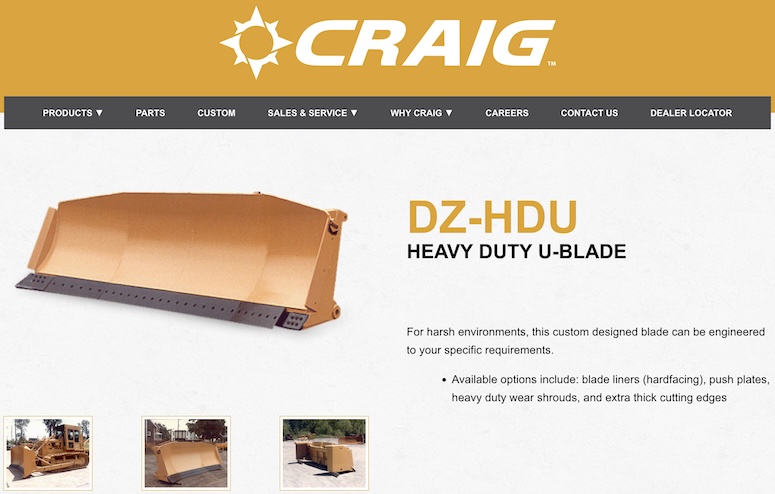

Craig

Craig Manufacturing Ltd. specializes in crafting custom-designed dozer blades tailored to meet the demands of harsh environments. Engineered to precise requirements, these blades offer a range of options, including blade liners, push plates, and heavy-duty wear shrouds, ensuring durability and performance. With dual cutting edges and sidewall rigidity, they enable efficient movement of large volumes of wood chips over long distances, making them the preferred choice for bio-thermal plants across North America.

- Range of dozer blades: Universal Blades, Landfill U-Blades, Woodchip U-Blades.

- Address: 408 Commerce Way Ethridge, Tennessee 38456, United States.

- Official website: craigattachments.com

Dymax

Dymax Heavy Duty Abrasion U-Dozer Blades are designed to excel in the most demanding mining environments. Featuring U-shaped wings, these blades offer enhanced load retention and higher capacities compared to conventional straight and Semi-U dozer blades. Equipped with rock guards, wear liners, white iron wear blocks, replaceable side shrouds, and vertical slat rock guards, Dymax univewrsal dozer blades ensure durability and performance. With 28-degree wing angles, they optimize capacities and material retention during operation (compatible with CAT, Komatsu, John Deere, Liebherr Crawler Dozers, and Track Type Tractors).

- Range of dozer blades: S-Blades, U-Blades, Coal / Landfill / Reclamation / Woodchip U-Blades, SU-Blades, A-Blades.

- Address: 402 Miller Dr, Wamego, KS 66547, United States

- Official website: dymaxinc.com

John Deere

John Deere (Deere & Company) is a renowned name in the agricultural and construction equipment industry, known for its commitment to quality and innovation. With a rich history spanning over a century, John Deere has established itself as a leader in providing reliable and efficient machinery to farmers, contractors, and landowners worldwide. Their extensive range of products, including excavators, dozers, and wheel loaders reflects their dedication to meeting the diverse needs of their customers. With a focus on technology-driven solutions and customer satisfaction, Deere & Company continues to set the standard for excellence in the industry.

- Range of dozer blades: The whole range of blades for Deere bulldozers (Straight Blades, 6-Way PAT Blades, etc.).

- Address: One John Deere Place Moline, IL 61265, United States.

- Official website: deere.com

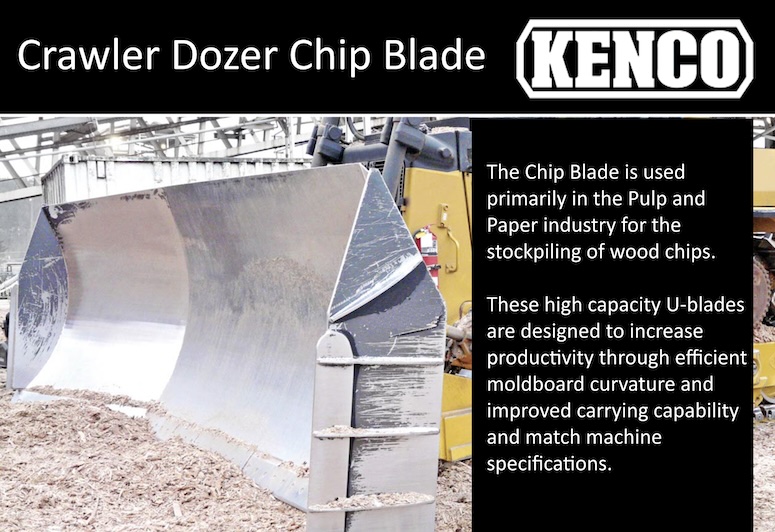

Kenco

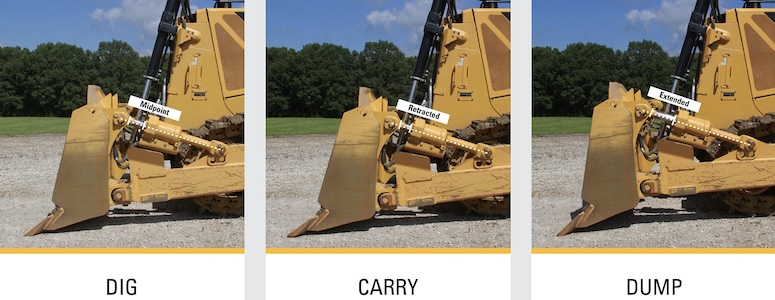

The Kenco Manual Angle Blade comes in standard (STD) and Low Ground Pressure (LGP) styles, offering compact designs for improved visibility, balance, and machine performance. The High Capacity Dozer Blade features optimal moldboard curvature for maximum carrying capacity, with an aggressive cutting edge angle for fast penetration and blade filling. The 6-Way Power Angle and Tilt Blade adds versatility, allowing for grading, trimming, sloping, ditching, and various other tasks without leaving the cab, available in semi-hydraulic or manual options.

- Range of dozer blades: Universal Blades, Woodchip U-Blades, Angle Blades, 6-Way PAT Blades.

- Address: 170 PA-271, Ligonier, PA 15658, United States.

- Official website: kenco.com

Komatsu

Komatsu America Corp. is a prominent player in the heavy equipment industry, offering a wide range of construction and mining machinery. With a focus on innovation and customer satisfaction, Komatsu provides cutting-edge solutions tailored to various applications. From excavators and bulldozers to dump trucks and wheel loaders, Komatsu’s products are known for their reliability, durability, and performance. With a strong presence in the North American market and a commitment to excellence, Komatsu America Corp. continues to be a trusted choice for heavy equipment needs.

- Range of dozer blades: S-Blades, U-Blades, Coal / Landfill / Reclamation / Woodchip U-Blades, SU-Blades, A-Blades, PAT-Blades, VPAT-Blades, Cushion Blades.

- Address: 8770 W. Bryn Mawr Ave., Suite 100 Chicago, IL 60631, United States

- Official website: komatsu.com

Liebherr

Liebherr USA, Co. stands as a leading force in the heavy equipment industry, renowned for its innovative solutions and high-quality machinery. With a diverse portfolio spanning construction, mining, and material handling equipment, Liebherr excels in meeting the demands of various industries. Leveraging advanced technology and a commitment to excellence, Liebherr products are known for their reliability, performance, and durability. With a strong presence in the United States and a global reputation for excellence, Liebherr USA, Co. continues to be a trusted partner for heavy equipment solutions.

- Range of dozer blades: PAT-Blades, VPAT-Blades, S-Blades, U-Blades, Coal U-Blades, Landfill / Reclamation / Woodchip U-Blades, SU-Blades, A-Blades, Cushion Blades.

- Address: 8770 W. Bryn Mawr Ave., Suite 100 Chicago, IL 60631, United States

- Official website: liebherr.com

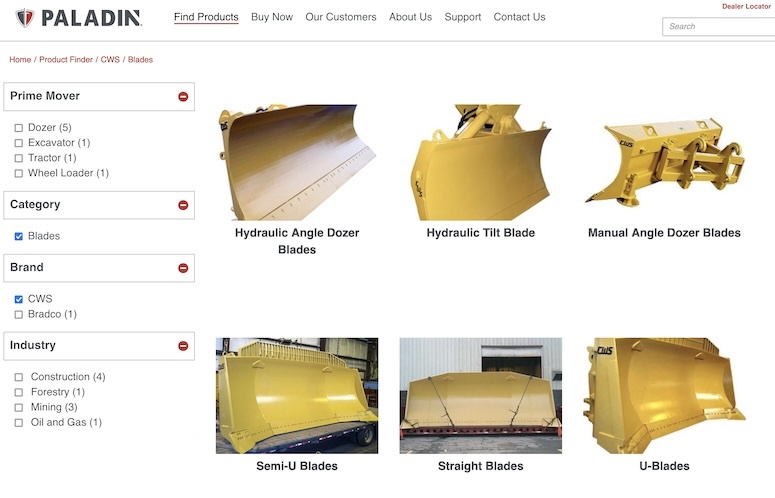

Paladin

With a diverse portfolio encompassing 11 brands, Paladin Attachments offers an extensive array of dedicated work tools tailored to meet the unique needs of every customer, from small compact tool carriers to large dozers. At the forefront of innovation, Paladin leads the market as a manufacturer of highly engineered attachment products, including dozer blades.

- Range of dozer blades: Universal Blades, Coal U-Blades, Woodchip U-Blades, Semi-Universal Blades, Angle Blades.

- Adress: 820 Glaser Parkway Akron, OH 44306 United States

- Official website: paladinattachments.com

Rockland

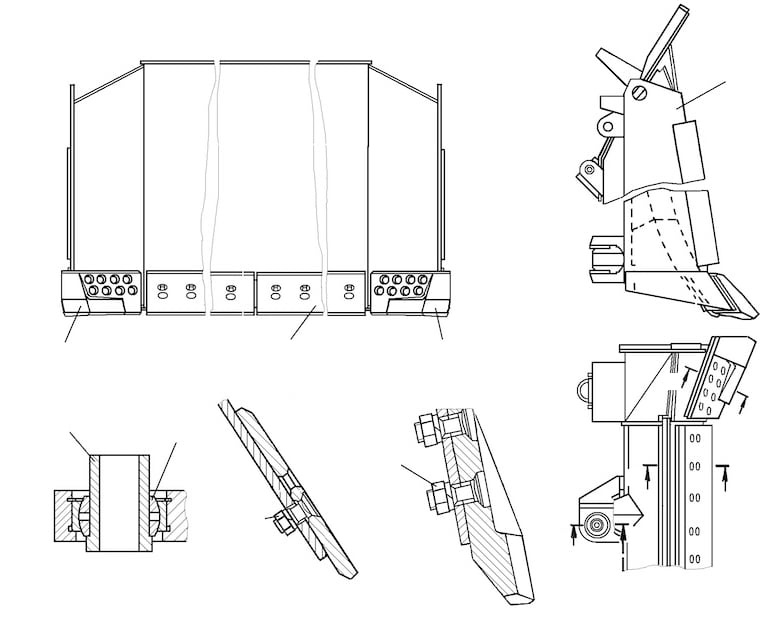

Rockland Manufacturing offers the versatile Universal, Semi-Universal Blades, Angle Blades, and Power Angle Tilt Blades, mountable on any bulldozer, ensuring strength and durability without compromising performance. With the ability to angle and tilt for efficient work, even in fully angled positions, it can doze paths wider than tracks, ideal for diverse dozing and grading tasks. Available for standard and low-ground pressure dozers, it features a full outside C-frame and hydraulic tilt struts for robustness, with options for blade liners and Carbide Embedded Hardfacing for extended reliability and durability.

- Range of dozer blades: Universal Blades, Coal U-Blades, Landfill / Reclamation / Woodchip U-Blades, Semi-Universal Blades, Angle Blades, PAT Blades.

- Address: 152 Weber Ln, Bedford, PA 15522, United States.

- Official website: rocklandmfg.com

These companies offer a range of bulldozer blades and attachments for various models and applications in the construction and mining industries.

Bulldozer Blade Types

Several factors influence the type of bulldozer blade used for a particular application Different blade types are suitable for various materials such as soil, rock, gravel, or debris. For example, a straight blade is ideal for general-purpose earthmoving, while a serrated blade is better suited for cutting through tough materials like rock or frozen ground. The terrain and environmental conditions of the work site, including slope, soil type, and ground conditions, impact blade selection. For instance, a U-blade with a curved profile is better suited for pushing and spreading material on uneven terrain, while a straight blade may be more effective on level ground.

Overall, choosing the right bulldozer blade involves considering these factors to ensure optimal performance and productivity for the specific job requirements.

| Dozer Blade Type | Best Results with | USA Manufacturers |

|---|---|---|

| Straight Blades (S Blade) | General earthmoving tasks – designed for basic earthmoving tasks such as grading, leveling, and pushing material. | Caterpillar, Komatsu, John Deere, Dymax, Paladin Attachments |

| Universal Blades (U Blade) | Various terrains and materials – suitable for a wide range of applications, including coal mining, landfill operations, reclamation projects, and woodchip handling. | Caterpillar, Komatsu, Liebherr, Craig, Kenco, Paladin Attachments, Bedrock Attachments |

| – Coal U-Blades | Coal mining operations – designed for handling coal and overburden materials in coal mining environments. | Caterpillar, Komatsu, Liebherr, Dymax, Rockland |

| – Landfill U-Blades | Landfill operations – optimized for use in landfill sites, capable of handling diverse materials and providing efficient compaction. | Caterpillar, Dymax, Komatsu, Rockland, Liebherr, Craig |

| – Reclamation U-Blades | Land reclamation projects – engineered for land reclamation projects, offering enhanced control and precision in reshaping terrain. | Caterpillar, Komatsu, Liebherr, Rockland, Dymax |

| – Woodchip U-Blades | Woodchip handling – designed for handling woodchips and other forestry materials, featuring high sides for containment and control. | Caterpillar, Dymax, Komatsu, Liebherr, Rockland, Kenco, Craig |

| Semi-Universal Blades (SU) | Varied applications – offering versatility for a range of tasks, combining features of both universal and straight blades. | Caterpillar, Komatsu, Liebherr, Dymax, Paladin Attachments, Rockland, Bedrock Attachments |

| Angle Blades (A Blade) | Trenching and backfilling – with adjustable angle capabilities, ideal for trenching, backfilling, and shaping ditches and embankments. | Caterpillar, Komatsu, Dymax, Paladin Attachments, Liebherr, Rockland, Kenco |

| Power Angle Tilt Blades (6-Way PAT) | Precision grading and shaping – equipped with power angle and tilt functions for precise grading, shaping, and contouring of terrain. | Caterpillar, John Deere, Komatsu, Liebherr, Kenco |

| Variable Pitch Power Angle Tilt Blades (VPAT) | Versatile grading and shaping – with variable pitch technology, offering enhanced versatility and control for grading and shaping tasks. | Caterpillar, Komatsu, Liebherr |

| Cushion Blades (CU Blade) | Rough terrain and uneven ground – featuring cushioning mechanisms to absorb impact and reduce stress on the machine and operator in rough terrain. | Caterpillar, Komatsu, Liebherr |

| Clearing Blades (V-shaped Blade) | Clearing snow, soil, debris, or other loose materials – features a V-shaped design that efficiently directs material away from the center, reducing resistance and allowing for smoother operation. Typically equipped with adjustable wings or side plates for versatile clearing width options | Rockland, Marden Industries, Savannah Global Solutions |

The specific tasks the bulldozer will perform influence blade choice. For example, a bulldozer used for grading and leveling may require a different blade type than one used for clearing brush or pushing debris. The desired finish of the surface being worked on also affects blade selection. Blades with features like tilt and angle adjustments provide greater control and precision, resulting in a smoother finish. The size and power of the bulldozer play a role in determining the appropriate blade size and weight capacity. Larger bulldozers can handle heavier and larger blades, allowing for more significant material movement.

Operator experience and preference may also influence blade selection. Some operators may have a preference for a specific blade type based on their experience and comfort level with different designs.

Dozer Blade Manufacturing Process

In the manufacturing process of dozer blades, one of the most important parts is the fabrication and shaping of the blade itself. This involves cutting and forming high-strength steel or other durable materials to precise specifications to ensure the blade’s strength, durability, and performance. Additionally, the welding and assembly processes play a crucial role in joining the various components of the blade securely, ensuring structural integrity and longevity. Finally, surface treatment processes such as painting or coating are essential to protect the blade from corrosion and wear, ensuring it can withstand the harsh conditions it will encounter in operation.

The bulldozer blade production process includes several key steps:

- Design and Engineering: Engineers and designers create blueprints and specifications for the blades, considering factors such as size, shape, material, and intended use.

- Material Selection: High-grade steel is commonly used for bulldozer blades due to its strength and durability. The selection of the appropriate steel alloy is critical to ensure the blade can withstand the rigors of heavy-duty work environments.

- Cutting and Forming: The steel sheets are cut into the required shapes using cutting tools such as lasers, plasma cutters, or water jets. The formed pieces are then shaped and bent to achieve the desired blade profile.

- Welding and Assembly: Various components of the blade are welded together to form the final structure. Welding techniques such as arc welding or robotic welding may be employed to ensure strong and uniform welds.

- Surface Treatment: The blade may undergo surface treatments such as sandblasting, priming, and painting to enhance corrosion resistance and improve aesthetics.

- Quality Control: Rigorous quality control measures are implemented throughout the production process to ensure that the blades meet industry standards and customer specifications. This may include dimensional inspections, material testing, and performance evaluations.

- Packaging and Shipping: Once the blades pass quality control checks, they are packaged and prepared for shipment to customers or assembly plants for installation onto bulldozers.

Overall, the production of bulldozer blades requires precision engineering, skilled craftsmanship, and adherence to strict quality standards to deliver reliable and high-performance equipment for construction, mining, and other heavy-duty applications.

Do manufacturers such as Caterpillar, John Deere, Komatsu, Liebherr or Volvo make dozer blades for other brands?

Typically, large heavy equipment manufacturers produce dozer blades only for their models!