Contents

- Dimensions

- Backhoe Working Range

- Loader Working Range

- Forklift Working Range

- Weight

- Engine Details

- Electrical System

- Transmission

- Hydraulic System

- Operator Environment

- Service Refill Capacities

- 500 Hour Filter Kit

- 1CXT Frequently asked questions

- How Much Can a JCB 1CXT Lift?

- What is the Bucket Capacity of the 1CXT?

- What is the Travel Speed of the 1CXT?

- How Much is the JCB 1CXT?

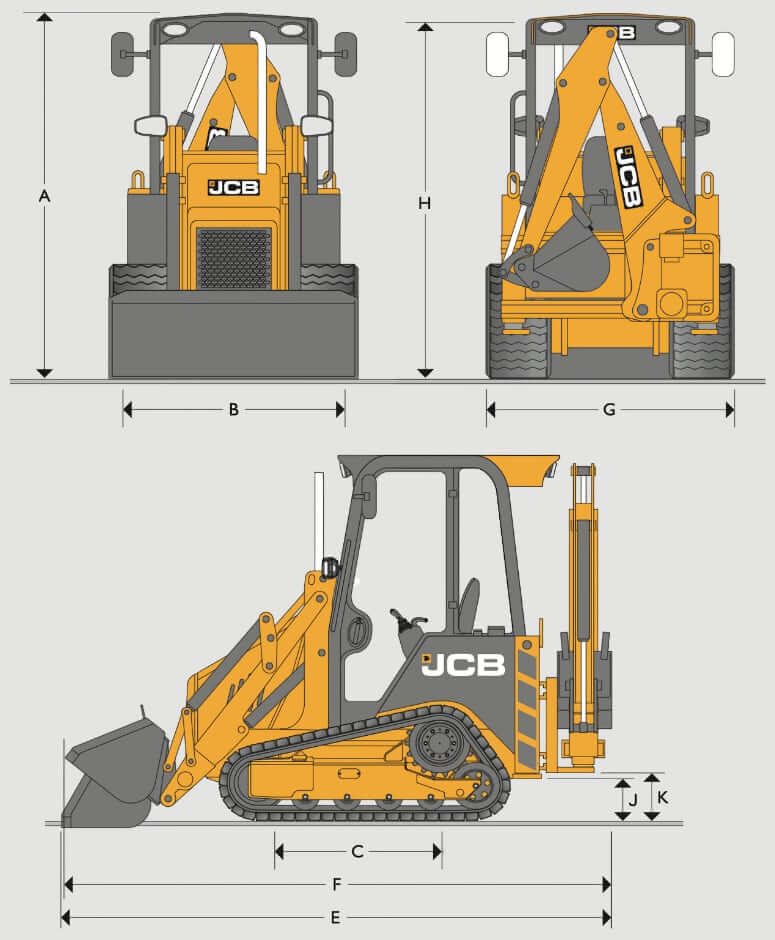

Dimensions

| A. Height to Cab Roof | 87.8 in (2230 mm) |

| B. Width Over Bucket | 70.9 in (1800 mm) |

| C. Axle Centerline Distance | 42.1 in (1070 mm) |

| E. Overall Travel Length | 140.6 in (3570 mm) |

| F. Overall Travel Length (Bucket in Carry Position) | 136.6 in (3470 mm) |

| G. Rear Frame Width (Over Stab Leg Feet) | 70.9 in (1800 mm) |

| H. Overall Travel Height (Fixed Dipper) | 86.6 in (2200 mm) |

| Overall Travel Height (Extending Dipper) | 89.4 in (2270 mm) |

| J. Stabilizer Feet Clearance | 10.2 in (260 mm) |

| K. Kingpost Clearance | 12.6 in (320 mm) |

| Ground Clearance | 10.2 in (258 mm) |

| Track Width | 2.6 in (320 mm) |

| Track Set footprint | 9 ft2 (0.85 m2) |

| Approach Angle | 60° |

| Departure Angle | 23° |

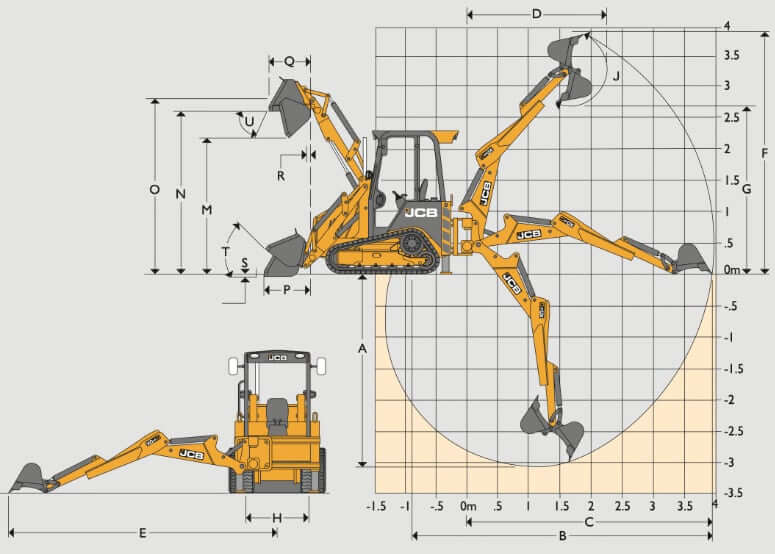

Backhoe Working Range

| Dimension | Fixed Dipper | Extended Dipper |

|---|---|---|

| A. Max Digging Depth (SAE) | 100.4 in (2550 mm) | 121.3 in (3080 mm) |

| B. Reach – Ground Level to Rear Axle Center | 166.9 in (4240 mm) | |

| C. Reach – Ground Level to Slew Center | 133.1 n (3380 mm) | 153.9 in (3910 mm) |

| D. Reach – at Full Height to Slew Center | 70.5 in (1790 mm) | 87.4 in (2220 mm) |

| E. Side Reach – to Centerline of Machine | 150.8 in (3830 mm) | 171.3. in (4350 mm) |

| F. Operating Height (SAE) | 135.4 in (3440 mm) | 152.0 in (3860 mm) |

| G. Max Loadover Height | 92.5 in (2350 mm) | 105.1 in (2670 mm) |

| H. Total Kingpost Travel | 46.8 in (1190 mm) | 46.8 in (1190 mm) |

| J. Bucket Rotation | 202° | 180° |

| Bucket Tearout | 4852 lbf (21.6 kN) | 4852 lbf (21.6 kN) |

| Dipper Tearout | 3280 lbf (14.6 kN) | 3280 lbf (14.6 kN) |

Loader Working Range

| M. Dump Height | 87 in (2210 mm) |

| N. Load-over Height | 104.3 in (2650 mm) |

| O. Loader Hinge Pin Height | 112.6 in (2860 mm) |

| P. Reach at Ground (Toe Plate Horizontal) | 55.5 in (1410 mm) |

| Q. Max. Reach at Full Height | 29.1 in (740 mm) |

| R. Reach at Full Height Fully Dumped | 15.7 in (400 mm) |

| S. Dig Depth (Toe Plate Horizontal) Clearance | 1.97 in (50 mm) |

| T. Roll Back at Ground | 42° |

| U. Dump Angle (SAE) | 43° |

| Loader Breakout – Bucket (SAE) | 5180 lbf (23.0 kN) |

| Loader Breakout – Arms | 5291 lbf (23.5 kN) |

| Max Lift Capacity (SAE) | 2204 lbf (9.8 kN) |

| Tipping Load | 4188 lb (1900 kg) |

| Rated Operating Capacity | 1466 lb (665 kg) |

| GP Bucket Capacity (Width 71″ / 1800 mm) | 0.48 yd3 (0.37 m3) |

| 6-in-1 Bucket Capacity (Width 71″ / 1800 mm) | 0.47 yd3 (0.36 m3) |

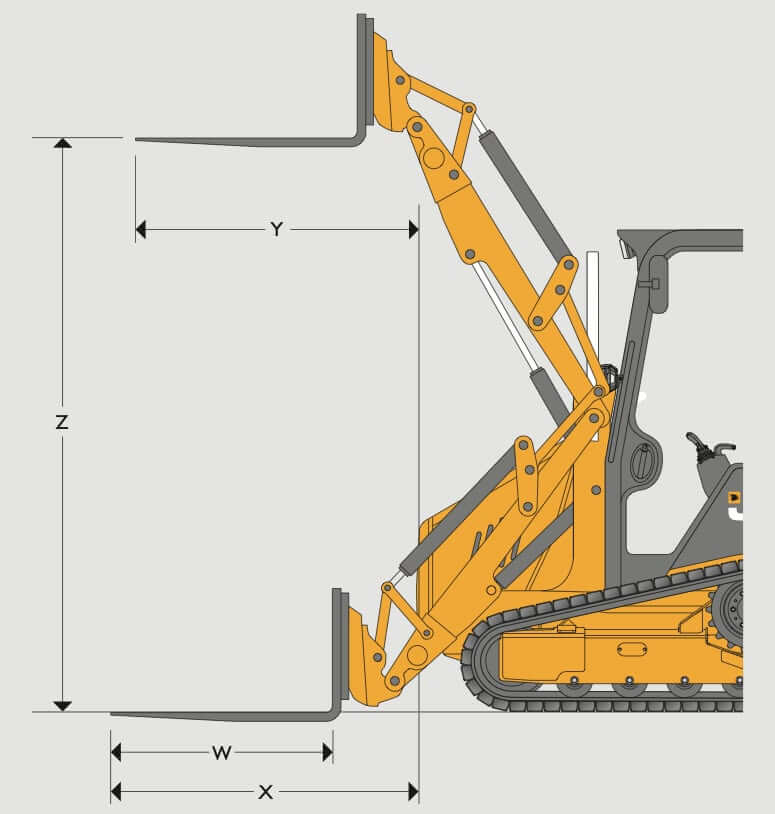

Forklift Working Range

| Quickhitch Mounted Forks | Long Arms |

|---|---|

| W. Tine Length | 41.3 in (1050 mm) |

| Tine Width | 3.1 in (80 mm) |

| X. Reach at Ground Level | 63 in (1600 mm) |

| Y. Reach at Full Height | 55.1 in (1400 mm) |

| Z. Max Lift Height | 111 in (2820 mm) |

| Min Fork Spacing | 7.9 in (200 mm) |

| Max Fork Spacing | 40.6 in (1030 mm) |

| Tipping Load @ 500 mm Load Centers Fixed Dipper | 2334 lb (1059 kg) |

| SWL @ 500 mm Load Centers Fixed Dipper | 815 lb (370 kg) |

| Tipping Load @ 500 mm Load Centers Extending Dipper | 2502 lb (1135 kg) |

| SWL @ 500 mm Load Centers Extending Dipper | 875 lb (397 kg) |

| Payload Rating as a Percentage of Tipping Load | 35% |

Weight

| Operating Weight (JCB 1CXT with Fixed Dipper) | 9396 lb (4262 kg) |

| Operating Weight (JCB 1CXT with Extended Dipper) | 9572 lb (4342 kg) |

Engine Details

| Number Of Cylinders | 4 |

| Engine Make | Perkins |

| Engine Model | Perkins 404F-E22T |

| Displacement | 134.3 cu in (2.2 L) |

| Bore | 3.3 in (84 mm) |

| Stroke | 3.9 in (100 mm) |

| Rated Power | 49 hp (36.3 kW) |

| Power Measured @ | 2800 rpm |

| Peak Torque | 122 lb ft (165 Nm) |

| Torque Measured @ | 1800 rpm |

| Fuel Filter | Replaceable cartridge plus water/sediment separator prefilter |

| Oil Filter | Full flow, spin-on type filter. Engine oil service intervals: 500 hours |

| Cooling system | Water, hot climate specification. Pressurised 1.0 bar, pusher fan |

| Aspiration | Turbocharged |

| Emission Standards | US EPA Tier 4 Final + EU Stage IIIA |

Electrical System

| Voltage | 12 V |

| Alternator | 50 amps (Optional: 85 amps) |

| Battery | 12 V, 72 Ah |

| Pre-Wire | Beacon |

| Warning System / Gauges | Fuel Level, hour meter. Audible and visual system. Ignition, working lights, park brake, alternator, main beam, engine oil pressure, water temp. |

| Working Lights | 2 adjustable front working lights + 2 adjustable rear working lights |

Transmission

| Transmission Make | Danfoss / Rexroth |

| Type | Hydrostatic Transmission |

| Max Forward Speed | 4.6 mph (7.5 km/h) |

| Max Reverse Speed | 4.6 mph (7.5 km/h) |

Hydraulic System

| Type | Open center 1CXT HF (high-flow) hydraulic system |

| Pump Type | Gear pump |

| Pump Flow Capacity (services) | 11.8 gal/min (45 L/min) |

| Pump Flow Capacity (high-flow) | 26.4 gal/min (100 L/min) |

| System Relief Pressure (Manual) | 3002 psi (20700 kPa) |

| System Relief Pressure (EasyControls) | 3190 psi (22000 kPa) |

Operator Environment

| Cab Type | Fully glazed ROPS/FOPS cab, road lights, face level fan, external mirrors, fire extinguisher, air filter pre-cleaner. (Optional: Canopy) |

| Noise Level (Intrelnal) | 82 dB(A) |

| Noise Level (External) | 101 dB(A) |

| Vibration (Whole body) | 0.29 m/s2 |

| Vibration (Hand arm) | Does not exceed 2.5 m/s2 for all duties with the exception of rough road tracking which averages 3.4 m/s2 |

| Cab Roof Height | 93.7 in (2380 mm) |

Service Refill Capacities

| Fuel Tank Capacity | 11.9 gal (45 L) |

| Engine Oil Capacity (With Filter) | 2.6 gal (9.6 L) |

| Cooling System Capacity | 2.2 gal (8 L) |

| Hydraulic System (Including Tank) | 11.9 gal (45 L) |

| Chain Cases | 2.6 gal (10 L) |

500 Hour Filter Kit

| Engine Oil Filter | Perkins 140517050 |

| Fuel Filter (2x) | JCB 32/401102, Perkins 4326658 |

| Hydraulic Filter (2x) | JCB 333/C4690 + JCB 581/18020 |

| Outer Air Filter | JCB 32/911801 |

1CXT Frequently asked questions

How Much Can a JCB 1CXT Lift?

Rated Operating Capacity (ROC): 1466 lb (665 kg) with the standard 6-in-1 bucket (ROC as determined according to ISO 14397: 2007, Includes extending dipper).

What is the Bucket Capacity of the 1CXT?

| Backhoe Buckets | Capacity SAE, Rated | Capacity SAE, Struck | Weight | Teeth |

|---|---|---|---|---|

| 9″ (230 mm) | 0.039 yd3 (0.03 m3) | 0.026 yd3 (0.02 m3) | 112 lb (51 kg) | 2 |

| 12″ (305 mm) | 0.052 yd3 (0.04 m3) | 0.052 yd3 (0.04 m3) | 114 lb (52 kg) | 3 |

| 18″ (460 mm) | 0.078 yd3 (0.06 m3) | 0.065 yd3 (0.05 m3) | 119 lb (54 kg) | 3 |

| 24″ (610 mm) | 0.105 yd3 (0.08 m3) | 0.078 yd3 (0.06 m3) | 125 lb (57 kg) | 4 |

| Ditching Buckets | Capacity SAE, Rated | Capacity SAE, Struck | Weight | Teeth |

| 39″ (1000 mm) | 0.16 yd3 (0.12 m3) | 0.13 yd3 (0.1 m3) | 114 lb (52 kg) | 0 |

What is the Travel Speed of the 1CXT?

The travel speed of the 1CXT is up to 4.6 miles per hour (7.5 km/h) in both forward and reverse directions. Due to its compact size & low weight, the JCB 1CXT is also easy to trailer and tow, often without a Commercial Driver’s License.

How Much is the JCB 1CXT?

The price of the JCB 1CXT can vary depending on factors such as location, dealer, optional features, and financing options. 2025 New JCB 1CXT price ≈ $90,000. For accurate pricing information, it’s recommended to contact your local JCB dealer or visit the manufacturer’s official website.

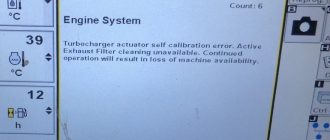

Can you help me figure out a fault code my machine is displaying – P1086-11. I’m not sure if -11 matters, but that’s what it says. Has been sitting a few months not moving. It starts no problem but idles real low and quiet. Won’t throttle up. Pull throttle handle up and engine doesnt change from weak idle. Also leaking engine oil. I’m not sure if that has anything to do with that. If you could give me an answer soon I’d appreciate it. I’m going to atemp to fix oil leak.I just need to know the fault code so I know what to check and fix it. thank you. Machine is a 1cxt tracked loader.

The fault code P1086-11 on your JCB 1CXT tracked backhoe loader points to a Fuel Rail Pressure Too Low condition — and specifically with static or slow response. Suffix “11” – General fault; often indicates permanent or active fault, not intermittent.

Likely Causes of P1086-11 on JCB 1CXT:

1) Low Fuel Rail Pressure Causes:

– Faulty fuel rail pressure sensor;

– Faulty or sticking fuel pressure relief valve or regulator;

– Weak or malfunctioning high-pressure fuel pump;

– Air or debris in the fuel lines (from sitting for months);

– Clogged fuel filter;

– Bad fuel (degraded diesel or water in fuel)

2) Electronic or Sensor Issues:

– Corroded connectors or damaged wiring to the fuel rail pressure sensor;

– ECU not receiving proper throttle position signal

3) Throttle Control Issues:

– Faulty electronic throttle actuator;

– Defective or stuck throttle position sensor;

– Rodent or moisture damage from sitting idle

Steps to Troubleshoot & Fix:

1. Visual inspection first – Check for rodent damage, chewed wiring, or disconnected sensors. Inspect the fuel rail sensor connector (often located on the common rail)

2. Check fuel system – Drain old fuel and replace with fresh diesel. Replace the fuel filter. Check for air in fuel lines (prime system if needed). Look for leaks in fuel supply or return lines

3. Test electronic system – Scan the machine with a JCB ServiceMaster diagnostic tool (if available). Test the fuel rail pressure sensor with a multimeter or diagnostic scan. Inspect and test the electronic throttle actuator

4. Identify source of oil leak — possibly related to injector seals, valve cover, or turbo oil feed line. Oil leaks can cause pressure loss or sensor contamination.