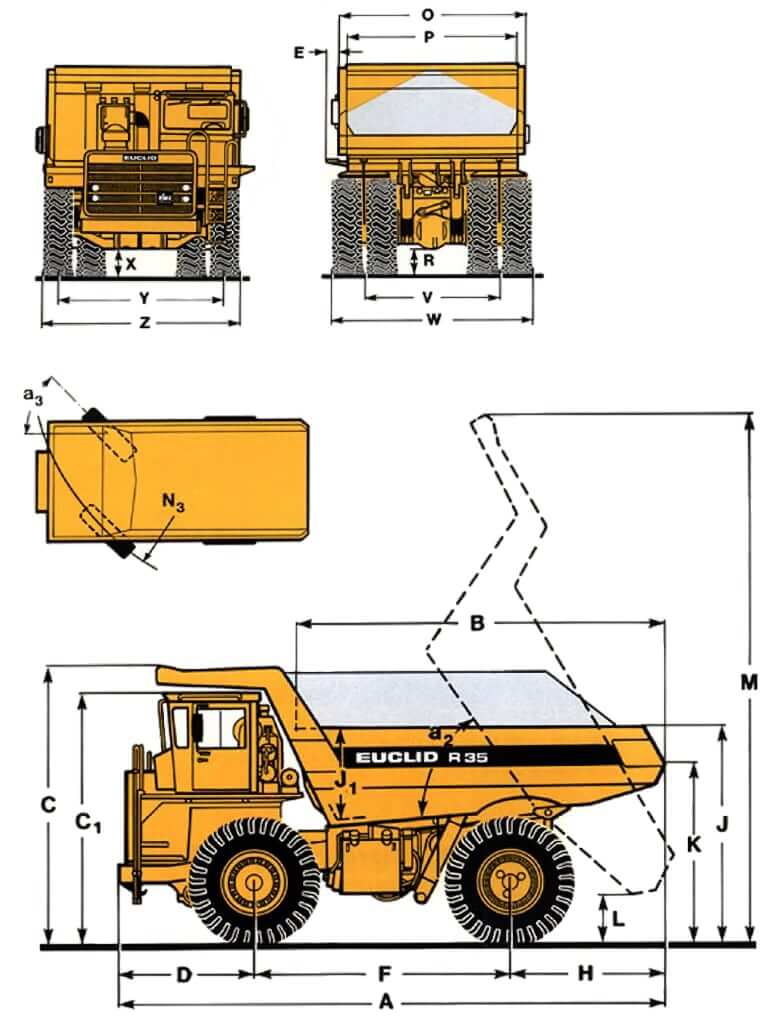

Dimensions

| A. Overall Length | 332.8 in (8200 mm) |

| B. Dump Body Length | 216.1 in (5490 mm) |

| C. Height to Top of Canopy | 162.9 in (4140 mm) |

| C1. Height to Top of Cab | 146.1 in (3710 mm) |

| D. Front Axle to Front | 85 in (2160 mm) |

| E. Width of Cab Platform | 11.8 in (300 mm) |

| F. Wheelbase | 146.9 in (3730 mm) |

| H. Rear Axle to Rear | 90.9 in (2310 mm) |

| J. Loading Height | 126.8 in (3220 mm) |

| J1. Dump Body Depth | 48 in (1220 mm) |

| K. Dump Body Rear Height | 103.3 in (2625 mm) |

| L. Tipper Clearance at Dump | 27.2 in (690 mm) |

| M. Max Height with Dump Body Raised | 311.8 in (7920 mm) |

| N3. Turning Radius | 317.7 in (8075 mm) |

| O. Dump Body Width (top) | 148 in (3760 mm) |

| P. Dump Body Width (bottom) | 137 in (3480 mm) |

| R. Ground Clearance (rear axle) | 20.9 in (530 mm) |

| V. Rear Track Width | 100 in (2540 mm) |

| W. Width Over Rear Tires | 144.9 in (3680 mm) |

| X. Ground Clearance (front axle) | 24 in (610 mm) |

| Y. Front Track Width | 122 in (3100 mm) |

| Z. Width Over Front Tires | 144.1 in (3660 mm) |

| a2. Dumping Angle | 60° |

| a3. Steering Angle | 42° |

Dump System

| Payload Capacity | 82894 lb (37600 kg) |

| Load Capacity – Struck | 22.2 yd3 (17.0 m3) |

| Load Capacity – Heaped | 30.5 yd3 (23.3 m3) |

| Body Raise Time | 11 sec |

| Body Tensile Strength | 1250 N/mm2 |

| Body Hardness | 360-440 HB |

| Plate Thickness (floor) | 0.60 in (16 mm) |

| Plate Thickness (front) | 0.30 in (8 mm) |

| Plate Thickness (sides) | 0.30 in (8 mm) |

| Plate Thickness (canopy) | 0.24 in (6 mm) |

Weights

| Max Operating Weight | 139380 lb (63220 kg) |

| Net Machine Weight | 62700 Ib (28440 kg) |

| Chassis w/ Hoists | 46800 Ib (21228 kg) |

| Body Weight | 15900 lb (7212 kg) |

| Front / Rear Axle Weight Distribution – Empty | 50% / 50% |

| Front / Rear Axle Weight Distribution – Loaded | 34% / 66% |

Engine Details

| Number Of Cylinders | 6 |

| Engine Make | Cummins |

| Engine Model | Cummins KT19-C |

| Displacement | 1147.3 cu in (18.8 L) |

| Bore | 6.25 in (159 mm) |

| Stroke | 6.25 in (159 mm) |

| Gross Power | 450.6 hp (336 kw) |

| Power Measured @ | 2100 rpm |

| Max Torque | 1406 lb ft (1906.3 Nm) |

| Torque Measured @ | 1500 rpm |

| Aspiration | Turbocharged |

| Fuel System | Direct Injection PT Pump |

Operational Specs

| Max Operating Weight | 139380 lb (63220 kg) |

| Payload Capacity | 82894 lb (37600 kg) |

| Operating Voltage | 24 V |

| Alternator | 75 amps |

| Battery | 2x 12 V, 205 Ah |

| Cab Width | 55.9 in (1420 mm) |

Transmission

| Type | Planetary type, full automatic shift transmission |

| Transmission Model | Allison CLT-5962 + Allison Transmission Electronic Control (ATEC) shift system |

| Torque Converter | Integral torque converter with automatic lock-up to lock-up shifting in all ranges |

| Number of Gears | 6F / 1R |

| Max Speed, Forward | 35.6 mph (57.2 km/h) |

| Max Speed, Reverse | 4.7 mph (7.5 km/h) |

Brake System

| Service Brakes | Air/oil actuated front disc brakes with one caliper per front disc. Calipers are internally ported, each containing three pairs of opposing pistons. Rear brakes are oil-cooled wet discs |

| Secondary Brakes | Two independent circuits within the service brake system provide secondary stopping capability conforming to SAE J1473. System is manually or automatically applied to stop machine within prescribed braking distance |

| Parking Brake | Drum, two shoe internal expanding type mounted behind transmission. Automatically applied if air pressure is lost. Manually controlled from instrument panel |

| Retarder | Foot operated valve controls air/oil- actuation of oil-cooled wet disc brakes on rear axle |

| Retarder Capacity | 585 hp (434 kw) |

Drive Axle and Suspension

| Drive Axle | Euclid Model 2052, full floating axle shafts, double reduction provided |

| Differential | Differential and single reduction planetary with balanced life gears in each wheel |

| Differential Ratio | 3.13:1 |

| Planetary Ratio | 6.00:1 |

| Total Reduction Ratio | 18.78:1 |

| Front / Rear Tire Size | 18.00-33 (28) ЕЗ |

| Front Axle Suspension | Independent trailing arm for each front wheel. Neocon struts containing energy absorbing gas and compressible Neocon-x fluid mounted between trailing arm and frame |

| Rear Axle Suspension | A-frame structure, integral with axle housing, links drive axle to frame at forward center point with pin and spherical bushing. Track rod provides rear link between frame and drive axle. Rear mounted Neocon struts suspend drive axle from frame |

Steering System

| Type | Open-centre system with separate hydraulic tank and independent gear pump |

| Pump | Independent gear pump |

| Cylinders | Hydraulic steering with two double-acting steering cylinders |

| Steering Pump Flow | 34 gal/min (129 L/min) |

| Steering Pump RPM | 2100 rpm |

| Relief Pressure | 2000 psi (13790 kPa) |

Hydraulic System

| Type | Separate hydraulic oil tank and independent tandem gear pump. Control valve mounted on hydraulic oil tank |

| Pump | Independent tandem gear pump |

| Cylinders | Two Euclid 2-stage, double-acting cylinders, inverted and outboard mounted |

| Hoist Pump Flow | 79 gal/min (299 L/min) |

| Hoist Pump RPM | 2100 rpm |

| Relief Pressure | 2500 psi (17237 kPa) |

| Body Raise Time | 11 sec |

Service Refill Capacities

| Fuel Tank Capacity | 120 gal (454 L) |

| Engine Oil Capacity (w/ filter) | 15.6 gal (59 L) |

| Cooling System Capacity | 37 gal (140 L) |

| Transmission Fluid Capacity (w/ filter) | 18.5 gal (70 L) |

| Hydraulic Tank Capacity (Steering) | 25.9 gal (98 L) |

| Hydraulic Tank Capacity (Hoist) | 46 gal (174 L) |

| Drive Axle Fluid Capacity | 14 gal (53 L) |

The Euclid R35 Haul Truck, produced between 1987 and 1995, is a mid-sized, rigid-frame dump truck designed for heavy-duty off-highway applications such as mining and large-scale earthmoving. Built under the WME Industries brand, this model is part of Euclid’s well-known R-Series lineup and features a robust design engineered for reliable performance and high productivity in challenging environments.

With a rated payload capacity of approximately 82894 lb (37600 kg), the R35 is powered by a high-torque diesel engine paired with an efficient drivetrain, delivering consistent hauling performance across rough terrains. Its sturdy box-section frame, wide stance, and rugged suspension system provide durability and stability during loaded operation. The truck’s spacious operator cab and straightforward mechanical layout also made it a favorite for ease of maintenance and driver comfort.

Popular throughout the late 1980s and early 1990s in quarry and mine operations around the world, the Euclid R35 remains a respected machine among legacy fleet operators and equipment collectors for its dependability, mechanical simplicity, and solid construction.