Contents

Dimensions

| Length to Fork Face | 144.2 in (3663 mm) |

| Wheelbase | 90 in (2286 mm) |

| Overall Width | 72 in (1829 mm) |

| Overall Height | 75.6 in (1920 mm) |

| Ground Clearance | 10.8 in (274 mm) |

| Cab Width | 34.3 in (870 mm) |

| Turning Radius Outside Tires | 126 in (3200 mm) |

Lift Performance

| Max Lift Height | 220 in (5588 mm) |

| Max Forward Reach | 131 in (3327 mm) |

| Rated Capacity at 24 in (610 mm) Load Center | 5500 lb (2495 kg) |

| Capacity at Max Lift Height | 4400 lb (1196 kg) |

| Capacity at Max Forward Reach | 1850 lb (839 kg) |

Lift Speed

| Lift Speed Up (boom retracted) | 6.2 sec |

| Lift Speed Down (boom retracted) | 4.3 sec |

| Telehandler Boom Speed (Extend) | 6.3 sec |

| Boom Speed (Retract) | 3.4 sec |

Tires

| Standard Tire Size | 14 x 17.5 Foam-Filled |

| Tire Size (Option 1) | 12 x 16.5 Foam-Filled |

| Tire Size (Option 2) | 14 x 17.5 Pneumatic |

| Tire Size (Option 3) | 30 x 12 Solid |

Engine Details

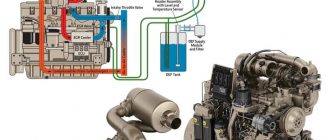

| Number of Cylinders | 4 |

| Engine Make | Perkins |

| Engine Model | Perkins 1104D-44T |

| Displacement | 268.4 cu in (4.4 L) |

| Displacement | 4.13 in (105 mm) |

| Displacement | 5.00 in (127 mm) |

| Gross Power | 84 hp (63 kw) |

| Power Measured @ | 2200 rpm |

| Peak Torque | 289 lb ft (392 Nm) |

| Torque Measured @ | 1400 rpm |

| Aspiration | Turbocharged |

| Emission Standards | US EPA Tier 3 + EU Stage IIIA |

Operational Specs

| Operating Weight | 10800 lb (4899 kg) |

| Operating Voltage | 12 V |

| Alternator | 75 amps |

| Battery | 12 V, CCA 950 |

| Breakout Force | 7650 lbf (34 kN) |

| Drawbar Pull | 8700 lb (3946 kg) |

| Dashboard | Panel and switches are illuminated for night operation |

Transmission

| Type | Hydrostatic transmission |

| Max Travel Speed | 17.1 mph (27.4 km/h) |

| Service Brakes | Wet Multi-Disc |

| Front Axle | High Bias, Limited Slip |

| Rear Axle | Oscillating |

Hydraulic System

| Pump Type | Single-section gear pump |

| Pump Flow Capacity | 19.1 gal/min (72.4 L/min) |

| Relief Valve Pressure | 3496 psi (24100 kPa) |

| Controls | Single joystick proportional controls |

| Hydraulic Oil Filtration | 10 micron filter with visual service indicator and suction strainer |

JLG G5-18A Attachments

| Standard Carriage | 50 in (1270 mm) |

| Side Tilt Carriage | 48 in (1219 mm) |

| Pallet Forks | 2 x 4 x 48 in (51 x 102 x 1219 mm) |

| Lumber Forks | 1.5 x 6 x 48 in (38 x 152 x 1219 mm) |

| Cubing Forks | 2 x 2 x 48 in (51 x 51 x 1219 mm) |

| General Purpose Bucket | 1.0 yd3 (0.76 m3) – 73 in (1854 mm) |

| Light Material Bucket | 1.7 yd3 (1.29 m3) – 72 in (1829 mm) |

| Grapple Bucket | 1.0 yd3 (0.76 m3) – 72 in (1829 mm) |

| Telehandler Lifting Hook | – |

| Universal Skid Steer Adapter | – |

Service Refill Capacities

| Fuel Tank Capacity | 24 gal (91 L) |

| Engine Oil Capacity (w/ filter) | 2.4 gal (9.1 L) |

| Cooling System Capacity | 3.6 gal (13.8 L) |

| Hydraulic System Capacity (w/ tank) | 23.5 gal (89 L) |

| Hydraulic Tank Capacity | 16.1 gal (61 L) |

| Front Differential Fluid Capacity | 0.9 gal (3.4 L) |

| Rear Differential Fluid Capacity | 0.9 gal (3.4 L) |

| Rear Hub Reductions (each) | 0.08 gal (0.3 L) |

| Wheel Drive Hub (each) | 0.08 gal (0.3 L) |

| Transferbox Oil Capacity | 0.16 gal (0.6 L) |

I have a new grapple that has worked correctly on a New Holland Tractor for the last 2 seasons and a lever under the seat is pushed to the left to open and to the right to close or vice versa as I really don’t remember which direction opens or closes. I connected the hydraulic line to a JLG G5 18-A telehandler and per the JLG manual; holding a button down and rocking the joystick to the left opens the grapple and holding the same button and rocking the joystick to the right closes it. What I have is when I hold the button down and rock the joystick to the right, the grapple opens and when I let go of the button, the grapple completely closes (it should stay open). Do you think reversing the hydro lines at the grapple would solve my problem?

On the JLG telehandler, the auxiliary hydraulic circuit is usually set up for continuous-flow tools (like hydraulic augers or sweepers). That’s why you have to hold the button – when you release it, the solenoid closes the circuit and the oil returns to tank. The result is: the grapple “relaxes” back closed instead of holding position.

Reversing the grapple hoses will only change which way it opens/closes with the joystick. It won’t fix the issue of the grapple not holding position after you release the button.

What you really need: A diverter or auxiliary valve with detent/hold function on the telehandler, so flow stays engaged until you move it back. Sometimes JLG telehandlers can be configured with a “clamp” or “auxiliary grapple” mode that holds hydraulic pressure when you release the button. You’d want to check in the operator’s or service manual to see if that option is available.