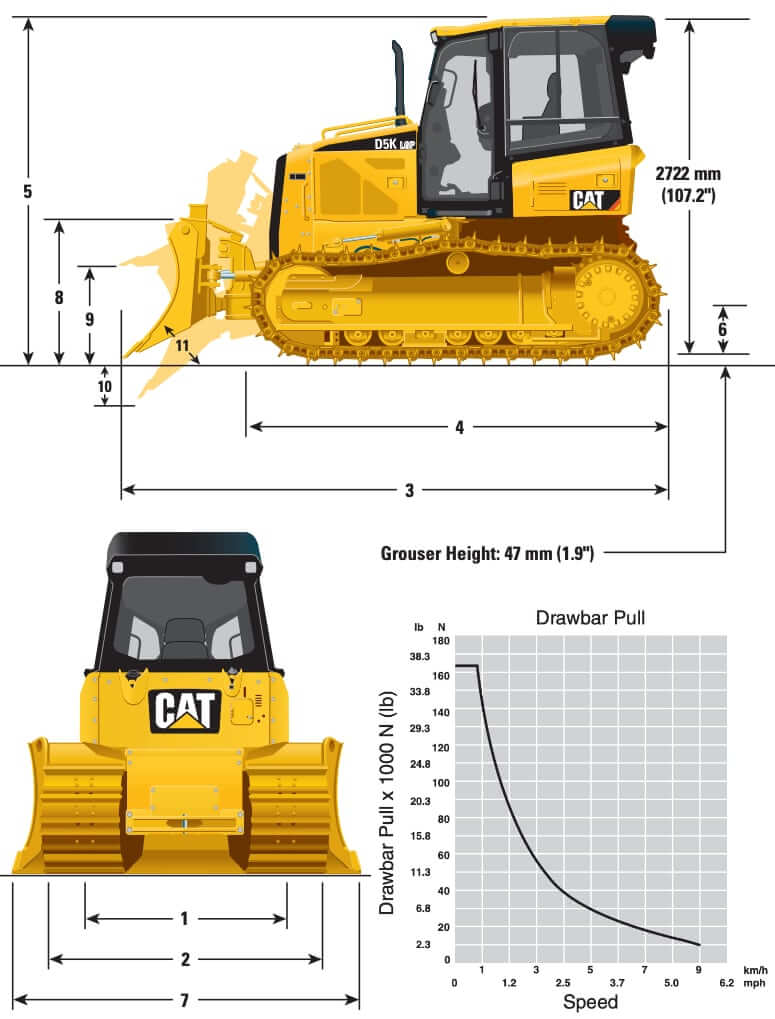

Dimensions

| CAT D5K Shoes | XL, 20 in (510 mm) | LGP, 26 in (660 mm) | LGP, 30 in (762 mm) |

|---|---|---|---|

| 1. Track Gauge | 63 in (1600 mm) | 68.9 in (1750 mm) | 73.2 in (1860 mm) |

| 2. Width of Tractor (standard shoes, no blade) | 83.1 in (2110 mm) | 94.9 in (2410 mm) | 103.5 in (2630 mm) |

| 3. Overall Length (with blade) | 170.1 in (4321 mm) | 169.1 in (4294 mm) | 169.1 in (4294 mm) |

| 4. Length of Basic Tractor (without blade) | 128.5 in (3265 mm) | 128.5 in (3265 mm) | 128.5 in (3265 mm) |

| 5. Overall Tractor Height (with ROPS/FOPS) | 109 in (2769 mm) | 109 in (2769 mm) | 109 in (2769 mm) |

| 6. Ground Clearance | 13 in (332 mm) | 13 in (332 mm) | 13 in (332 mm) |

Dozer Blade

| CAT D5K | XL Blade | INTMD Blade | LGP Blade |

|---|---|---|---|

| 7. Blade Width | 109.5 in (2782 mm) | 115 in (2921 mm) | 126.7 in (3220 mm) |

| 8. Blade Height | 42.2 in (1073 mm) | 39.8 in (1010 mm) | 39.8 in (1010 mm) |

| 9. Blade Lift Height | 30.2 in (767 mm) | 30.2 in (767 mm) | 30.2 in (767 mm) |

| 10. Digging Depth | 23.1 in (586 mm) | 22.5 in (572 mm) | 22.5 in (572 mm) |

| 11. Blade Cutting Edge Angle, Adjustable | 52° to 58° | 52° to 58° | 52° to 58° |

| Max Tilt | 15.8 in (402 mm) | 17.6 in (448 mm) | 17.6 in (448 mm) |

| Max Angle (either side) | 25° | 25° | 25° |

| Blade Width at Max Angle | 103.8 in (2636 mm) | 105.1 in (2669 mm) | 115.8 in (2940 mm) |

| Blade Capacity (SAE) | 2.86 yd3 (2.19 m3) | 2.73 yd3 (2.09 m3) | 3.06 yd3 (2.34 m3) |

Undercarriage

| CAT D5K | XL, 20 in (510 mm) | LGP, 26 in (660 mm) | LGP, 30 in (770 mm) |

|---|---|---|---|

| Length of Track on Ground | 91 in (2310 mm) | 91 in (2310 mm) | 91 in (2310 mm) |

| Track Gauge | 63 in (1600 mm) | 69 in (1750 mm) | 73.2 in (1860 mm) |

| Ground Contact Area | 3652 in2 (23562 cm2) | 4726 in2 (30492 cm2) | 5514 in2 (35574 cm2) |

| Ground Pressure | 5.67 psi (39.1 kPa) | 4.52 psi (31.1 kPa) | 3.93 psi (27.1 kPa) |

| Grouser Height | 1.9 in (47 mm) | 1.9 in (47 mm) | 1.9 in (47 mm) |

| Number of Track Rollers per Side | 7 | 7 | 7 |

| Number of Shoes per Side (SALT Undercarriage) | 40 | 40 | 40 |

| Number of Shoes per Side (SystemOne Undercarriage) | 36 | 36 | 36 |

Winch

| Model | Cat PA40 |

| Winch Weight | 1345 lb (610 kg) |

| Winch Drive | Hydrostatic |

| Speed | Variable |

| Winch Length | 27.8 in (705 mm) |

| Overall Width | 29.2 in (741 mm) |

| Drum Diameter | 10 in (254 mm) |

| Drum Width | 10.8 in (274 mm) |

| Throat Clearance | 6.75 in (171.5 mm) |

| Control | Hydraulic |

| Rope Diameter – Recommended | 0.63 in (16 mm) |

| Rope Diameter – Optional | 0.75 in (19 mm) |

| Drum Capacity – Recommended Cable | 371 ft (113 m) |

| Drum Capacity – Optional Cable | 256 ft (78 m) |

| Maximum Line Pull – Bare Drum | 40000 lb (18144 kg) |

| Maximum Line Pull – Full Drum | 25000 lb (11340 kg) |

| Maximum Line Speed – Bare Drum | 131 ft/min (40 m/min) |

| Maximum Line Speed – Full Drum | 207 ft/min (63 m/min) |

Ripper

| Number of Shanks | 3 |

| Ripper Type | Parallelogram |

| Ripper Weight | 1222 lb (554 kg) |

| Max Digging Depth | 13.3 in (337.5 mm) |

| Max Reach at Ground Line | 21.9 in (555 mm) |

| Max Ground Clearance Under Tip | 17.6 in (448 mm) |

| Ripper Width | 67.3 in (1710 mm) |

| Ripper Height | 6.5 in (165 mm) |

Engine Details

| Number of Cylinders | 4 |

| Engine Make | Caterpillar |

| Engine Model | Cat C4.4 ACERT |

| Displacement | 269 cu in (4.4 L) |

| Bore | 4.13 in (105 mm) |

| Stroke | 5.00 in (127 mm) |

| Gross Power | 100 hp (74.5 kw) |

| Net Power | 96 hp (71.6 kw) |

| Power Measured @ | 1900 rpm |

| Compression Ratio | 16.5:1 |

| Rotation (from flywheel end) | Counterclockwise |

| Fuel System | Direct injection |

| Air Cleaner | Air cleaner with precleaner, automatic dust ejection and under-hood intake |

| Aspiration | Turbocharged Aftercooled |

| Emission Standards | US EPA Tier 3 + EU Stage IIIA + Japan MOC Step 3 |

Operational Specs

| Operating Weight, XL | 20741 lb (9408 kg) |

| Operating Weight, LGP | 21347 lb (9683 kg) |

| Operating Voltage | 12 V |

| Alternator | 120 amps |

| Battery | 2x 12 V, CCA 900 |

| Starter | 12 V, 6.7 hp (5 kw), 11 teeth |

Operating with dozer blade, canopy ROPS, operator, coolant, lubricants and full fuel tank

Operator Environment

| Canopy (Standard) | ROPS / FOPS canopy with heater |

| Cab (Optional) | Cab with sliding side windows, heater and air conditioning |

| Operator Seat | Adjustable air suspended seat, cloth or vinyl |

| Operator Seat (Optional) | Cloth, heated and ventilated seat with heated controls |

| Seat Belt | Retractable seat belt 3 in (76 mm) |

| AccuGrade System | AccuGrade Laser Display / AccuGrade GPS Display / AccuGrade Monitor |

| Working Lights | 2x front halogen lights and 1x rear halogen light |

| Working Lights (Optional) | Integrated 4x front halogen lights + 2x rear halogen lights |

| ROPS | SAE J397-OCT95, SAE J1040-MAY94, ISO 3471-94, ISO 3164-95 |

| FOPS | SAE J231-JAN81, ISO 3449-92 |

| Sound Level (ANSI/SAE J1166) | 80 dB(A) |

Transmission

| Type | Dual path, closed loop, hydrostatic transmission |

| Number of Gears | Infinite forward and reverse |

| Max Forward Speed | 5.6 mph (9.0 km/h) |

| Max Reverse Speed | 6.2 mph (10.0 km/h) |

| Drive Pumps | Two variable-displacement, slipper-axial piston pumps mounted tandemstyle to engine flywheel housing |

| Track Motors | Two variable-displacement, link-type piston motors |

| Final Drives | Double-reduction planetary gear set. Mounted independently of track frames |

| Steering | Single lever steering, speed and direction control |

| Service Brakes | Hydrostatic braking through machine drive system using transmission control lever, center brake pedal or decel pedal |

Hydraulic System

| Type | Load sensing hydraulics with 3 valves |

| Hydraulic System w/ 4 Valves (Optional) | Four valve for use with ripper |

| Hydraulic System w/ 4 Valves (Optional) | Four valve for use with winch |

| Main Pump Flow | 19.4 gal/min (73.5 L/min) |

| Relief Valve Setting | 2988 psi (20600 kPa) |

| Control Positions, Lift cylinders | Raise, hold, lower, float |

| Control Positions, Tilt cylinders | Left, hold, right |

| Control Positions, Angle cylinders | Left, hold, right |

| Control Positions, Ripper cylinders | Raise, hold, lower |

| Hydraulic Filters | Filters are all located in the left rear service compartment and are accessible from ground level |

Service Refill Capacities

| Fuel Tank Capacity | 51.5 gal (195 L) |

| Engine Oil Capacity | 2.9 gal (11 L) |

| Cooling System Capacity | 5.9 gal (22.4 L) |

| Transmission / Hydraulic System Capacity (w/ tank) | 22.2 gal (84 L) |

| Hydraulic Tank Capacity | 15.7 gal (59.5 L) |

| Winch Housing Capacity | 1.2 gal (4.7 L) |

| Final Drives Capacity (each side), XL | 2.6 gal (10 L) |

| Final Drives Capacity (each side), LGP | 2.6 gal (10 L) |

The Cat D5K Dozer, available in XL and LGP configurations, is engineered to deliver exceptional grading performance, balance, and versatility for construction, forestry, and site preparation work. Built around Caterpillar’s advanced hydrostatic drive and stable undercarriage design, the D5K offers precise control and smooth power delivery in a compact yet powerful package.

At the heart of its earthmoving capability is the Variable Pitch, Power Angle, and Tilt (VPAT) blade, available in multiple configurations to match job requirements. The XL VPAT blade provides excellent balance between capacity and maneuverability, ideal for general construction and finish grading. The LGP VPAT blade pairs with a wider, low-ground-pressure undercarriage for superior flotation in soft or wet conditions. The Intermediate VPAT blade offers an option tailored for mid-range capacity and ground contact, giving operators a balance of productivity and stability.

For additional functionality, the D5K can be equipped with a heavy-duty drawbar for towing applications, a winch mounting system for forestry or recovery work, and a parallelogram ripper fitted with three shanks and teeth for breaking up compacted soil or rock. This combination of blade options and rear attachments makes the D5K a highly adaptable dozer, capable of tackling fine grading, bulk pushing, site clearing, and subsoil preparation with equal efficiency.