- List of Kubota Tractor Error Codes

- Error Codes P0016 – P3025 (Engine DTCs)

- Error Codes U0075 – U0089

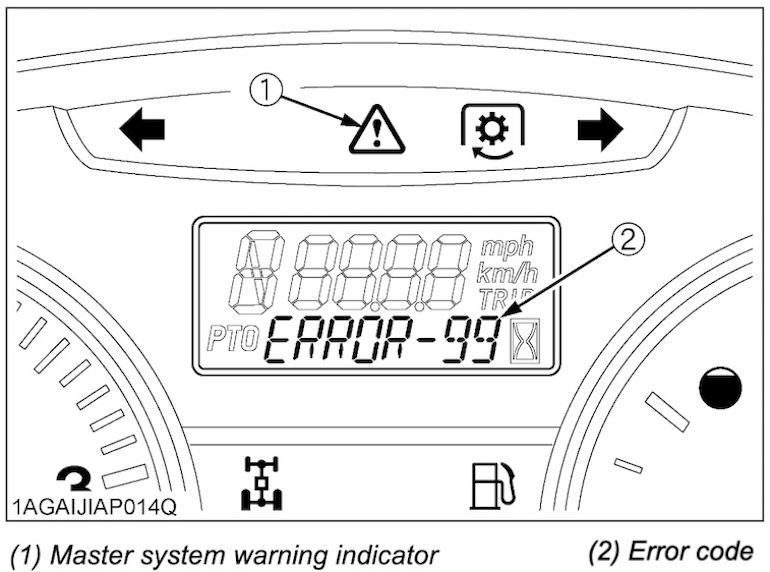

- Fault Codes ERROR 00 – 99

- Error Codes E-R20 – E-R55

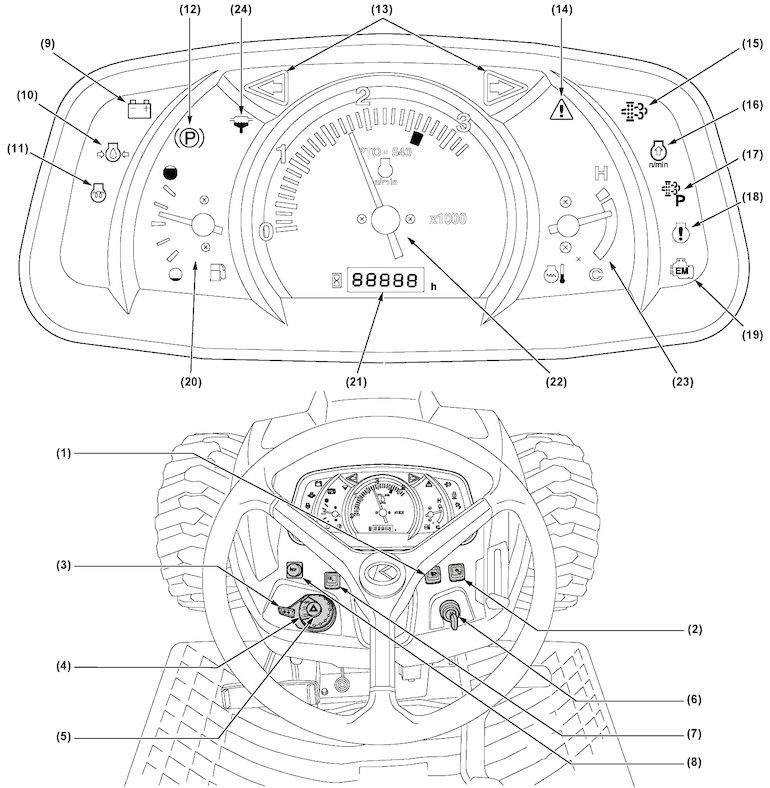

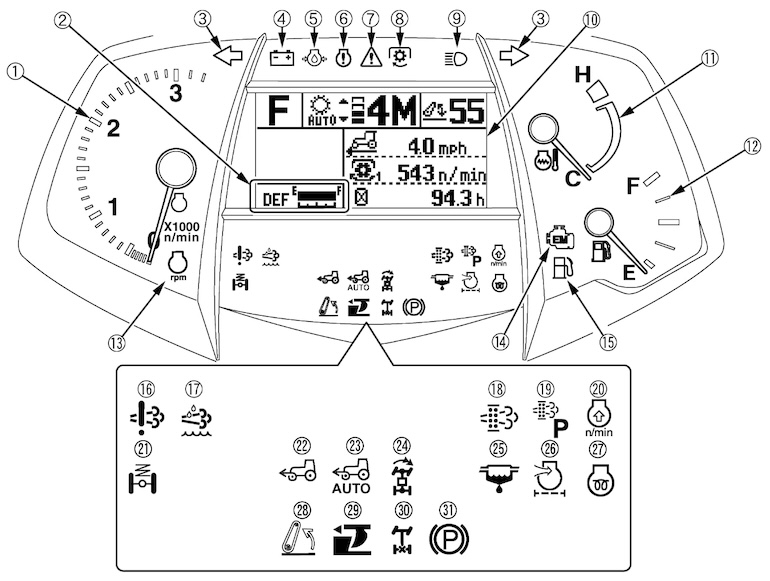

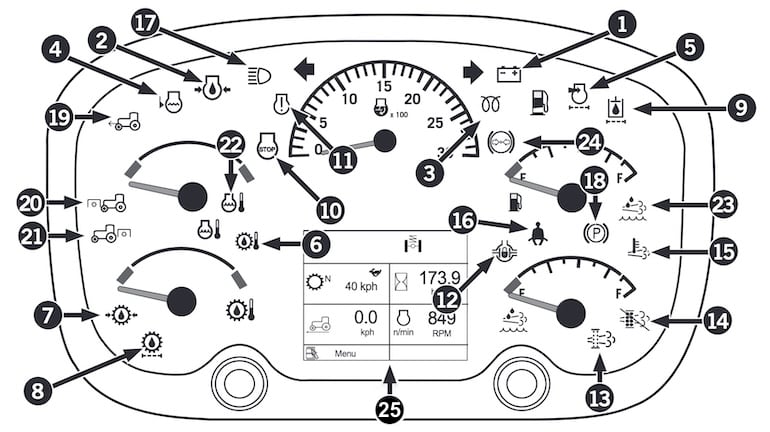

- Kubota Tractor Dashboard Lights / Symbols

- MX Series Indicators & Warning Lights

- M6 Series Indicators & Warning Lights

- M8 Series Indicators & Warning Lights

- How To Reset Kubota Error Codes?

Kubota Tractor Error Codes, often referred to as DTC Fault Errors, are a vital aspect of modern tractor diagnostics. These codes serve as a form of communication between the tractor and its operator, highlighting potential problems within the machinery. By deciphering these error codes, tractor owners and technicians can quickly identify issues, enabling timely and accurate troubleshooting.

In this comprehensive guide, we’ll delve into the realm of Kubota Tractor Error Codes, exploring their significance, common codes, and what they mean for tractor operators and mechanics alike. These codes are your Kubota tractor’s way of communicating what’s wrong, making it easier for owners and technicians to diagnose and resolve problems efficiently.

List of Kubota Tractor Error Codes

Understanding these codes is not just about maintaining your tractor’s health; it’s about ensuring your work continues smoothly, whether you’re plowing fields, landscaping, or tending to any other critical task. So, let’s decode the language of Kubota Tractor Error Codes to keep your work on track.

Error Codes P0016 – P3025 (Engine DTCs)

Keep your Kubota tractor running smoothly, minimize downtime, and ensure optimal performance, all while potentially saving on costly repairs! So, let’s embark on a journey through the world of Kubota tractor engine DTCs, demystifying the language of your tractor’s diagnostics and empowering you to keep your equipment in prime working condition.

| Error Number | Tractor Engine Error Description |

|---|---|

| P0016 | Crankshaft position sensor (NE) – cylinder recognition sensor (G) phase gap |

| P0072 | Intake air temperature built-in MAF sensor abnormality: Low |

| P0073 | Intake air temperature built-in MAF sensor abnormality: High |

| P0087 | Pressure limiter opening abnormality |

| P0088 | High rail pressure abnormality |

| P0089 | SCV stuck |

| P0093 | Fuel leak (Leak in high pressure fuel circuit) |

| P0101 | Intake Air Volume: Low |

| P0102 | MAF Sensor Abnormality: Low |

| P0103 | MAF Sensor Abnormality: High |

| P0112 | Intake air temperature sensor abnormality |

| P0113 | |

| P0117 | Coolant temperature sensor abnormality |

| P0118 | |

| P0182 | Fuel temperature sensor abnormality |

| P0183 | |

| P0192 | Rail pressure sensor abnormality |

| P0193 | |

| P0200 | Overcharge |

| P0201 | TWV 1 actuation system open circuit |

| P0202 | TWV 2 actuation system open circuit |

| P0203 | TWV 3 actuation system open circuit |

| P0204 | TWV 4 actuation system open circuit |

| P0217 | Engine overheat. (Check cooling system; as coolant, radiator net, fan belt tension) |

| P0219 | Engine Overrun |

| P0237 | Intake air pressure sensor abnormality |

| P0238 | |

| P0263 | Non-injection abnormality (rotational fluctuation abnormality) |

| P0266 | |

| P0269 | |

| P0272 | |

| P0335 | Crankshaft position sensor (NE sensor) abnormality |

| P0336 | |

| P0340 | Cylinder Recognition Sensor (G sensor) abnormality |

| P0341 | |

| P0380 | Air heater relay actuation abnormality (optional specifications) |

| P0381 | Glow heater relay driving circuit overheat |

| P0400 | EGR feedback abnormality |

| P0403 | EGR actuator open circuit |

| P0404 | EGR actuator coil short / EGR DC motor estimated temperature abnormality |

| P0405 | EGR lift sensor abnormality |

| P0406 | |

| P0409 | EGR position sensor failure |

| P0501 | Vehicle speed sensor abnormality |

| P0503 | |

| P0524 | Oil pressure error |

| P0543 | Exhaust gas temperature sensor 1 (T1) abnormality: Low |

| P0544 | Exhaust gas temperature sensor 1 (T1) abnormality: High |

| P0546 | Exhaust gas temperature sensor 0 (T0) abnormality: Low |

| P0547 | Exhaust gas temperature sensor 0 (T0) abnormality: High |

| P0561 | Battery voltage abnormality |

| P0562 | |

| P0563 | |

| P0602 | QR abnormality (IQA Data Error) |

| P0605 | ECU Flash – ROM abnormality |

| P0606 | CPU abnormality |

| P0611 | Low charge |

| P0616 | Starter switch abnormality |

| P0617 | |

| P0627 | Open Circuit of SCV |

| P0628 | SCV abnormality |

| P0629 | |

| P062B | Injector Abnormality |

| P062D | Internal injector drive circuit short |

| P0642 | Sensor voltage 1 abnormality |

| P0643 | |

| P0652 | Sensor voltage 2 abnormality |

| P0653 | |

| P0662 | Sensor Supply Voltage 3 Abnormality |

| P0687 | Main relay abnormality |

| P081A | GND Short Circuit of Start Relay Driving Circuit |

| P1274 | Pump protection failure flag |

| P1275 | Pump replacement failure flag |

| P1990 | EEPROM check sum error |

| P204F | DEF/AdBlue level is too low |

| P20F5 | DEF/AdBlue level is too low |

| P208B | DEF/AdBlue freeze warning |

| P2108 | Intake throttle feedback error |

| P2122 | Accelerator position sensor 1 abnormality |

| P2123 | |

| P2127 | Accelerator position sensor 2 abnormality |

| P2128 | |

| P2131 | Accelerator Position Sensor Error (CAN) |

| P2135 | Accelerator position sensor correlation error |

| P2146 | Common 1 system open circuit |

| P2147 | Common 1 TWV actuation system ground short |

| P2148 | Common 1 TWV actuation system +B short |

| P2149 | Common 2 system open circuit |

| P2151 | No.2 & 3 cylinder injector short to +B |

| P2227 | Atmospheric pressure sensor abnormality |

| P2228 | Atmospheric pressure sensor abnormality |

| P2229 | Atmospheric pressure sensor abnormality |

| P2293 | Rail pressure sensor abnormality after pressure limiter open |

| P2294 | Fuel Pressure Regulator 2 Control Circuit Open |

| P2413 | EGR actuator valve stuck |

| P2414 | EGR (DC motor) Overheat |

| P2415 | EGR (DC motor) temperature sensor failure |

| P242C | Exhaust gas temperature sensor 2 (T2) abnormality: Low |

| P242D | Exhaust gas temperature sensor 2 (T2) abnormality: High |

| P2454 | Differential Pressure Sensor 1 Abnormality: Low |

| P2455 | Differential Pressure Sensor 1 Abnormality: High |

| P2621 | Intake Throttle Lift Sensor Abnormality: Low |

| P2622 | Intake Throttle Lift Sensor Abnormality: High |

| P3001 | Emission deterioration |

| P3002 | Exhaust gas temperature sensor 0 emergency High |

| P3003 | Exhaust gas temperature sensor 1 emergency High |

| P3004 | Exhaust gas temperature sensor 2 emergency High |

| P3006 | Excessive PM3 |

| P3007 | Excessive PM4 |

| P3008 | Excessive PM5 |

| P3011 | Boost pressure low |

| P3012 | Low coolant temperature in parked regeneration |

| P3013 | Parked regeneration time out |

| P3018 | All exhaust gas temperature sensor failure |

| P3023 | High exhaust gas temperature after emergency high temperature |

| P3024 | High frequency of regeneration |

| P3025 | Over heat pre-caution |

Full List of Kubota Engine Errors (P0016 – P2414) with Descriptions

Error Codes U0075 – U0089

| Error Number | Error Description |

|---|---|

| U0075 | CAN2 Bus off |

| U0076 | No Communication with EGR (523578-2) |

| U0077 | CAN1 Bus off |

| U0081 | CAN-KBT Frame error |

| U0082 | CAN CCVS frame error |

| U0083 | CAN CM1 frame error |

| U0086 | CAN ETC5 frame error |

| U0087 | CAN TSC1 frame error |

| U0089 | CAN EBC1 frame error |

Fault Codes ERROR 00 – 99

| Error Number | Kubota Tractor Error Description |

|---|---|

| E00 | IntelliPanel’s memory device is in trouble |

| E-1 | Acceleration sensor (main) trouble |

| E-2 | Acceleration sensor (sub) trouble |

| E-3 | Acceleration sensor main/sub phase shifting trouble |

| E-4 | Shuttle sensor (main) trouble |

| E-5 | Shuttle sensor (sub) trouble |

| E-6 | Shuttle sensor main/sub phase shifting trouble |

| E-7 | Shuttle sensor signal trouble |

| E-8 | Gear lock signal trouble |

| E-11 | PTO relay trouble |

| E-12 | 4WD solenoid trouble |

| E-13 | Bi-speed turn solenoid trouble |

| E-14 | Shuttle forward solenoid trouble |

| E-15 | Shuttle forward solenoid trouble |

| E-17 | Differential lock solenoid valve trouble |

| E-20 | Communication error between ECU and electronic instrument panel |

| E-21 | Range gear shift (Hi) switch trouble |

| E-22 | Main gear shift (6th) switch trouble |

| E-23 | Shuttle rotating sensor trouble |

| E-24 | Machine speed sensor trouble |

| E-25 | DPF regeneration malfunction trouble |

| E-30 | ECU memory device is in trouble |

| E-31 | Part code of meter and ECU model setting not compatible |

| E-40 | Input voltage of lever sensor from ECU is in trouble |

| E-41 | Engine communication trouble |

| E-42 | ACU communication trouble |

| E-43 | ECU communication trouble or meter communication trouble |

| E-50 | GST lever sensor is in trouble |

| E-60 | Proportional reducing valve failure |

| E-61 | Solenoid 1 is in trouble |

| E-62 | Solenoid 2 is in trouble |

| E-63 | Solenoid 3 failure |

| E-64 | Solenoid 4 failure |

| E-65 | Solenoid 5 failure |

| E-66 | Solenoid 6 failure |

| E-75 | Acceleration sensor output out of spec |

| E-84 | Acceleration sensor maladjusted |

| E-93 | Relay for engine-starter-motor is in trouble |

| E-94 | Relay for engine-shut-off is in trouble |

| E-95 | Solenoid (PTO) is in trouble |

| E-99 | Communication trouble |

| ENG NG | Engine communication trouble |

| ECU NG | ECU communication trouble |

| ERROR-NET | Communication trouble |

Error Codes E-R20 – E-R55

| Error Number | Kubota Tractor Error Description |

|---|---|

| E-R20 | Trouble with the output voltage of the clutch pedal sensor. A Clutch pedal sensor trouble / Shift lock switch trouble occur at the same time. |

| E-R31 | Trouble with the relevant solenoid valve. A Proportional solenoid valve (range shift L/H) trouble |

| E-R32 | |

| E-R33 | |

| E-R34 | |

| E-R35 | |

| E-R36 | |

| E-R37 | Proportional solenoid valve (master) trouble. |

| E-R38 | Shifting is performed using the shift buttons. A Hydraulic switch trouble. A Main spool trouble |

| E-R39 | |

| E-R40 | |

| E-R41 | |

| E-R42 | |

| E-R43 | |

| E-R44 | Started by operation of the shift buttons, shuttle lever, and clutch pedal. A Trouble with master clutch hydraulic switch trouble. A Low system hydraulic pressure. |

| E-R45 | Trouble with a hydraulic switch that is not related to the flashing gear speed. A Hydraulic switch trouble. A Main spool trouble |

| E-R46 | |

| E-R47 | |

| E-R48 | |

| E-R49 | |

| E-R 50 | |

| E-R51 | Clutch is operated. A Hydraulic switch (master) trouble. A Proportional solenoid valve (master) trouble. Shift lock switch trouble occur at the same time. |

| E-R52 | Trouble with a hydraulic switch that is not related to the flashing gear speed. A Hydraulic switch trouble. A Main spool trouble |

| E-R53 | |

| E-R54 | |

| E-R55 |

Kubota Tractor Dashboard Lights / Symbols

Kubota tractors, like many modern vehicles and machinery, come equipped with a dashboard that features various lights and symbols. These dashboard indicators serve as a vital communication tool between your tractor and you, the operator. Understanding what each Kubota dash light or symbol means is crucial for safe and efficient tractor operation.

MX Series Indicators & Warning Lights

Kubota MX series multipurpose tractor instrument panel and controls (MX5400, MX5400 Cab, MX6000, MX6000 Cab, etc):

- DPF INHIBIT switch.

- Parked regeneration switch.

- Turn signal light switch.

- Head light switch.

- Hazard light switch.

- Key switch.

- Stationary PTO switch.

- Horn button [CAB type only].

- Electrical charge warning indicator.

- Engine oil pressure warning indicator.

- Glow plug indicator.

- Parking brake warning indicator.

- Turn signal / hazard light indicator.

- Master system warning indicator.

- Regeneration indicator.

- Engine RPM increase indicator.

- Parked regeneration.

- Engine warning indicator.

- Emission indicator.

- Fuel gauge.

- Hour meter.

- Tachometer.

- Coolant temperature gauge.

- Water separator filter indicator

M6 Series Indicators & Warning Lights

Kubota M6 series mid-size utility tractor instrument panel and controls (M6-101, M6-111, M6-131, M6-141, etc):

- Tachometer.

- DEF / AdBlue gauge.

- Turn signal / Hazard light indicator.

- Electrical charge warning indicator.

- Engine oil pressure warning indicator.

- Engine warning indicator.

- Master system warning indicator.

- PTO clutch indicator.

- High-beam indicator.

- Liquid crystal display.

- Coolant temperature gauge.

- Fuel gauge.

- Constant RPM management indicator.

- Emission indicator.

- Fuel level indicator.

- DEF / AdBlue system warning indicator.

- DEF / AdBlue warning indicator.

- Regeneration indicator.

- Parked regeneration indicator.

- Engine RPM increase indicator.

- Front suspension indicator [Front suspension type].

- 4WD indicator.

- Auto 4WD indicator.

- Bi-speed turn indicator.

- Water separator indicator.

- Air cleaner indicator.

- Heater indicator.

- 3-Point Lifting / Lowering indicator.

- Draft indicator.

- Rear wheel differential lock indicator.

- Parking brake warning indicator

M8 Series Indicators & Warning Lights

Kubota M8 series row crop tractor instrument panel and controls (M8-181, 8-201, etc):

- Alternator Charge Indicator: Illuminates steady and sounds an alarm if alternator is not charging battery.

- Engine Oil Pressure: Illuminates when low engine oil pressure is detected.

- Inlet Heater/Ready to Start: Illuminates when key is turned to the run position and is cold enough outside to activate grid heater.

- Coolant Level Low: Illuminates when coolant in reservoir is low.

- Air Filter Restriction: Illuminates if a fault has existed for 10 seconds.

- Transmission Oil Temperature: Flashes when high transmission oil temp detected (above 99ºC / 210 ºF).

- Transmission Oil Pressure: Illuminates and sounds an alarm indicating low transmission oil pressure.

- Transmission Oil Filter: Illuminates indicating a filter bypass condition due to a blocked filter.

- Hydraulic Oil Filter: Illuminates indicating a filter bypass condition and no longer filtering oil returning to the reservoir.

- Stop Engine: Illuminates when a critical condition has been detected.

- Engine Warning Light: Yellow for non-critical and maintenance and red for critical faults.

- Differential Locks (option): Illuminates when the differential lock button is engaged on tractors equipped with differential locks.

- Diesel Particulate Filter (DPF) light: DPF filter is filling — may be flashing and / or used with the engine stop or warning light.

- Regeneration inhibit light on: Regeneration has been stopped.

- High exhaust temperature light on: Higher than normal exhaust temperatures may exist due to DPF regeneration.

- Seat Belt: Illuminates when the ignition switch is turned to the RUN position and stays illuminated for 5 seconds to remind the operator to fasten the seat belt.

- High Beams: Illuminates when tractor lights are switched to high beam.

- Parking Brake: Illuminates when the parking brake is applied. (Absent Operator Warning: If you leave the operator seat for more than 3 seconds while the engine is running, the parking brake lamp will flash and an audible alarm will sound.)

- Front Wheel Assist: When the service brake pedals are applied, the front wheel assist is automatically activated so that both front and rear wheels assist in braking.

- Front PTO: Illuminates when front pto is enabled.

- Rear PTO: Illuminates when rear pto is enabled.

- Engine Coolant Temperature: Illuminates when engine coolant temperature has risen above acceptable limits.

- Diesel Exhaust Fluid (DEF): DEF level is low.

- Brake Pressure is Normal: This icon will appear if the brake pressure is normal.

From engine-related warnings to reminders about essential maintenance tasks, Kubota dash lights and symbols are designed to keep you informed and your tractor running smoothly. Explore our guide to become well-versed in the language of your Kubota tractor’s dashboard and make informed decisions about its operation and maintenance.

How To Reset Kubota Error Codes?

Resetting Kubota tractor error codes, also known as Diagnostic Trouble Codes (DTCs), can sometimes be necessary to clear a fault and get your tractor back to normal operation.

However, please note that resetting DTCs should only be done after the underlying issue has been identified and resolved. Resetting codes without addressing the problem may lead to further issues or potential safety hazards.

Here are the general steps to reset Kubota tractor error codes:

- Identify the Issue: Before attempting to reset any error codes, it’s crucial to understand why the code was triggered in the first place. Check the operator’s manual or consult with a qualified technician to determine the nature of the problem.

- Address the Problem: Resolve the underlying issue causing the error code. This might involve repairing or replacing faulty components, adjusting settings, or performing routine maintenance.

- Turn Off the Engine: Ensure the tractor’s engine is turned off, and the key is in the off position.

- Locate the Diagnostic Connector: Depending on your Kubota tractor model, the diagnostic connector may be located in different areas. Common locations include under the dashboard, near the engine, or within the engine compartment. Refer to your tractor’s manual to find the exact location.

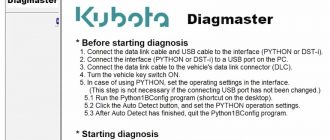

- Use Diagnostic Tool (Optional): Some Kubota tractors may require a diagnostic tool to reset error codes. If your tractor model requires this tool, connect it to the diagnostic port according to the manufacturer’s instructions.

- Turn the Key to the “On” Position: Without starting the engine, turn the tractor’s ignition key to the “On” position. This usually means the position just before the engine cranks.

- Read and Clear the Codes: If you’re using a diagnostic tool, follow its prompts to read and clear the error codes. Most modern diagnostic tools have an option to erase codes. If you’re not using a tool, you may need to follow a specific sequence of actions like pumping the accelerator pedal or pressing certain buttons on the dashboard. Refer to your tractor’s manual for guidance.

- Turn Off the Ignition: Once the error codes have been cleared, turn off the tractor’s ignition.

- Wait a Moment: Some tractors may require a brief moment of key-off time for the codes to reset properly.

- Restart the Engine: After a brief pause, start the tractor’s engine. Ensure that the error code no longer appears on the display or instrument panel.

Remember that not all Kubota tractor models and error codes are the same, so always consult your tractor’s manual for specific instructions related to your equipment.

If you’re unsure or unable to resolve an error code, it’s best to contact a Kubota service technician or dealer for professional assistance.

I have a Kubota m5-091 tractor. The error codes ‘Eng P- 0102’ and ‘Eng P-1A1E’ are flashing on the dashboard screen. How can I correct this?

P-0102 – This code often refers to an issue with the Mass Air Flow (MAF) Sensor. Specifically, it could mean the airflow signal is too low or missing.

Possible Causes: dirty or clogged air filter / faulty or disconnected MAF sensor / wiring issue or loose connections leading to the sensor / restricted airflow due to debris in the intake.

Steps to Resolve: Ensure it is clean and free from obstructions. Replace if necessary. Look for signs of dirt or damage. Clean it carefully using MAF cleaner. Ensure the sensor’s connector is secure and there is no visible damage to the wires. After addressing the issue, restart the tractor and check if the error persists.

P-1A1E – This code is related to the Exhaust Gas Recirculation (EGR) System. It may indicate an issue with the EGR valve position or flow.

Possible Causes: clogged EGR valve or passages / malfunctioning EGR valve / sensor or wiring issue in the EGR system / excessive soot buildup in the exhaust system.

Steps to Resolve: Check for soot buildup or clogs in the valve and passages. Remove the valve if needed and clean it thoroughly with a suitable solvent. Ensure all connections are secure and undamaged.Use a Kubota diagnostic tool to clear the code after performing maintenance

thanks

Kubota l3901 code p2294. Code will not clear and code is not in the manual. Called a dealer and spoke with someone and they have no idea of this code.

Error code P2294 (Diagnostic trouble code OBD-II) – “Fuel Pressure Regulator 2 Control Circuit/Open”. If the PCM (powertrain control module) detects a problem with the fuel pressure regulator (designated #2) or its circuit, then it might trigger DTC code P2294. This code can be caused by a faulty fuel pressure regulator, faulty fuel pump, wiring issues, or a failed PCM.

I have a Kubota M9960 after a major repair, the computer showed an error EN9 NG and it only spins but doesn’t start, help

The EN9 NG error on your Kubota M9960 tractor usually points to a problem with the Engine Control Unit (ECU) not receiving a necessary signal or detecting a critical fault, most commonly related to:

1. Crankshaft Position Sensor (CKP) Failure – If the ECU can’t detect engine rotation correctly, fuel injection won’t be activated. Check sensor connector, wiring continuity, and proper mounting gap.

2. Camshaft Position Sensor Issue – Also affects injection timing; failure leads to no start and EN9 code. Inspect for damage or disconnection.

3. Fuel System Not Primed or Air-locked – After major repairs, air in the lines can prevent fuel delivery. Solution: Fully bleed the fuel system — start from tank, filter, pump to injectors.

4. ECU Ground or Power Problem – could indicate ECU is failing self-checks. Check battery voltage, fuses, and all ECU grounds.

5. Immobilizer or Security Lockout – After disconnection of battery/ECU during major repairs, security lock may block ignition. Solution: Check key fob or reinitialize security module (requires dealer tool).

6. Sensor or Harness Left Disconnected – During major repairs, something may have been left unplugged. Action: Do a full wiring check, especially to ECU, sensors, and fuel injection components.

Steps for Troubleshooting:

1) Try a Hard Reset:

– Disconnect battery terminals for 5–10 minutes.

– Reconnect and turn key ON (without starting) for 30 seconds.

– Attempt restart.

2) Check Diagnostic Codes with KUBOTA Diagnostic Tool (KTM or dealer-level) – this will read full error logs and help you isolate which sensor/circuit failed.

3) Fuel Cut Solenoid & Relay Check – ensure the fuel shut-off solenoid is getting power and operating correctly.

I was shredding on M6 140 hp Kubota. Stopped pto then when I engaged again got ER85 code. Anyone have a clue what that code is?

On a Kubota M6 tractor, the ER85 error code generally indicates a PTO clutch engagement error — specifically, it means: The PTO clutch is not engaging or disengaging correctly.

Since you mentioned you stopped the PTO and then got the ER85 error when trying to re-engage, it fits perfectly – the system detected an issue while trying to activate the PTO clutch.

It might be electrical (like a sensor or switch issue) or mechanical (the clutch itself struggling to engage properly).

Common causes for ER85 error code:

– PTO clutch coil or solenoid fault;

– Wiring issue to the PTO control;

– Faulty PTO switch;

– Low system voltage;

– Hydraulic pressure too low for clutch engagement;

– Physical wear or failure inside the clutch mechanism.

You can try:

– Turn the tractor completely off, wait a minute, and restart.

– Check battery voltage — low voltage can throw clutch errors.

– Inspect PTO wiring and connectors for looseness or damage.

– Test if PTO will engage under no load (without an implement attached).

If the code stays after reset, it likely needs dealer diagnostics with a Kubota scanner to check live PTO clutch signals.