Loader Performance

| Tipping Load | 11874 lb (5386 kg) |

| Rated Operating Capacity (ROC) (35% Tipping Load) | 4156 lb (1885 kg) |

| Rated Operating Capacity (ROC) (50% Tipping Load) | 5937 lb (2693 kg) |

| Operating Capacity with Counterweight (35% Tipping Load) | 4435 lb (2011 kg) |

| Breakout Force (Tilt Cylinder) | 9963 lbf (44.3 kN) |

| Breakout Force (Lift Cylinder) | 6422 lbf (28.6 kN) |

| Standard Bucket Width | 80 in (2036 mm) |

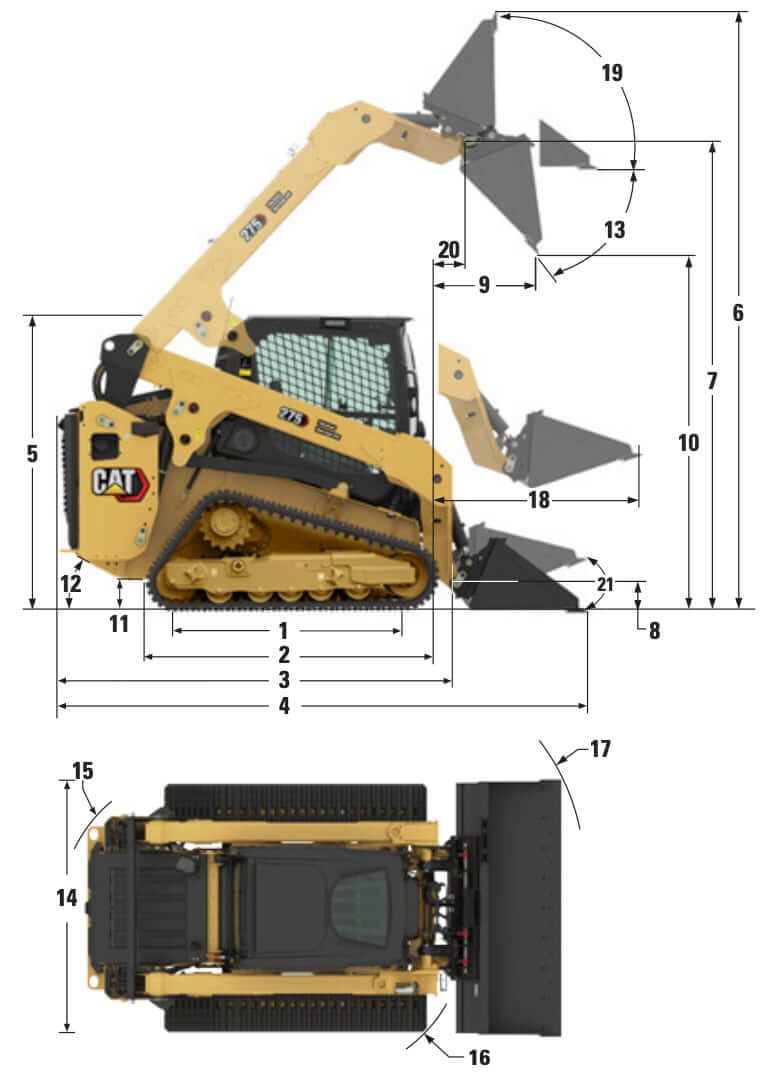

Dimensions

| 1. Length of Track on Ground | 72.3 in (1836 mm) |

| 2. Overall Length of Track | 92.2 in (2341 mm) |

| 3. Length without Bucket | 128.0 in (3250 mm) |

| 4. Length with Bucket on Ground | 152.8 in (3880 mm) |

| 5. Height to Top of Cab | 87.8 in (2230 mm) |

| 6. Max Overall Height | 165.1 in (4193 mm) |

| 7. Bucket Pin Height at Max Lift | 134.4 in (3415 mm) |

| 8. Bucket Pin Height at Carry Position | 8.1 in (205 mm) |

| 9. Reach at Max Lift and Dump | 32.0 in (814 mm) |

| 10. Clearance at Max Lift and Dump | 106.1 in (2694 mm) |

| 11. Ground Clearance | 11.0 in (280 mm) |

| 12. Departure Angle | 29.5° |

| 13. Max Dump Angle | 44.7° |

| 14. Overall Width with 15.7 in (400 mm) Tracks | 75.8 in (1926 mm) |

| 14. Overall Width with 17.7 in (450 mm) Tracks | 77.8 in (1976 mm) |

| 15. Turning Radius from Center – Machine Rear | 76.0 in (1931 mm) |

| 16. Turning Radius from Center – Coupler | 60.3 in (1531 mm) |

| 17. Turning Radius from Center – Bucket (racked) | 91.3 in (2320 mm) |

| 18. Max Reach with Arms Parallel to Ground | 46.1 in (1171 mm) |

| 19. Rack Back Angle at Max Height | 86.7° |

| 20. Bucket Pin Reach at Max Lift | 16.3 in (415 mm) |

| 21. Bucket Rollback Angle (ground level) | 27.3° |

Undercarriage

| Track Shoe Size (Standard) | 15.7 in (400 mm) |

| Track Shoe Size (Wide) | 17.7 in (450 mm) |

| Length of Track on Ground | 72.3 in (1836 mm) |

| Ground Contact Area (15.7 in / 400 mm tracks) | 2496 in2 (1.61 m2) |

| Ground Contact Area (17.7 in / 450 mm tracks) | 2808 in2 (1.81 m2) |

| Ground Pressure (15.7 in / 400 mm tracks) | 5.1 psi (35.1 kPa) |

| Ground Pressure (17.7 in / 450 mm tracks) | 4.5 psi (31.3 kPa) |

| Track Frame | Integrated tie downs on track frame (4) |

| Suspension | E-bar (equalizer bar) suspension |

Engine Details

| Number of Cylinders | 4 |

| Engine Make | Caterpillar |

| Engine Model | Cat C3.6TA |

| Displacement | 221 cu in (3.6 L) |

| Bore | 3.9 in (98 mm) |

| Stroke | 4.7 in (120 mm) |

| Gross Horsepower | 111 hp (82 kw) |

| Net Horsepower | 109 hp (81 kw) |

| Power Measured @ | 2400 rpm |

| Peak Torque | 370 lb ft (501 Nm) |

| Torque Measured @ | 1500 rpm |

| Fuel System | Direct injection |

| Compression Ratio | 17.0:1 |

| Aspiration | Turbocharged and aftercooled |

| Aftertreatment | DOC+DPF or DOC+DPF+SCR |

| Emission Standards | US EPA Tier 4 Final + EU Stage V |

Operational Specs

| Operating Weight (Cab) | 12619 lb (5724 kg) |

| Operating Weight (Canopy) | 12401 lb (5625 kg) |

| Counterweight (Optional) | 428 lb (194 kg) |

| Max Operating Lift Capacity | 5937 lb (2693 kg) |

| Operating Voltage | 12 V |

| Alternator | 100 amps (85 amps) |

| Battery | 12 V, CCA 1000 heavy duty battery |

| Work Lights | LED Work Lights |

Operator Environment

| Operator Station | Open Canopy or Enclosed Cab |

| Cab (Optional) | Enclosed Cab with heat and air conditioning (with R134a refrigerant) |

| ROPS | ISO 3471:2008 |

| FOPS | ISO 3449:2005 Level I / Level II |

| Technology Package T2 | Standard Monitor, Standard Joysticks, traditional Key Start switch, and Rear-view camera |

| Technology Package T4 | Advanced Touchscreen Monitor, Advanced Joysticks, Push start, X-mount cell phone holder, and a Rear-view camera |

| Technology Package T5 | T4 + 2 additional side view cameras |

| Sound Level (interior) | 82 dB(A) |

| Sound Level (exterior) | 105 dB(A) |

Power Train

| Type | Hydrostatic transmission |

| Number of Gears | Standard two-speed travel |

| One Travel Speed (Forward / Reverse) | 5.2 mph (8.4 km/h) |

| Two Travel Speed (Forward / Reverse) | 7.8 mph (12.5 km/h) |

| Parking Brake | Spring applied, hydraulically released, park brake |

Hydraulic System

| CAT 275 with | Standard Hydraulics | High Flow | High Flow XPS |

|---|---|---|---|

| Pump Flow Capacity | 23 gal/min (86 L/min) | 34 gal/min (129 L/min) | 34 gal/min (128 L/min) |

| Relief Valve Pressure | 3500 psi (24130 kPa) | 3500 psi (24130 kPa) | 4061 psi (28000 kPa) |

| Hydraulic Power | 46.4 hp (34.6 kw) | 69.6 hp (51.5 kw) | 80.7 hp (60.2 kw) |

Service Refill Capacities

| Fuel Tank Capacity | 36 gal (136.1 L) |

| DEF Tank Capacity | 2.9 gal (11 L) |

| Engine Oil Capacity | 2.4 gal (9.0 L) |

| Cooling System Capacity | 4.6 gal (17.5 L) |

| Hydraulic System Fluid Capacity | 10.8 gal (41.0 L) |

| Hydraulic Tank Capacity | 6.9 gal (26.0 L) |

Designed to pair with a large portfolio of Cat work tools, Cat 275 can be equipped for digging, grading, cutting, lifting, trenching, snow clearing, and more, making it a true all-season, all-purpose machine.

Operators can choose from an extensive lineup of attachments, including augers for drilling, backhoes for excavation, buckets and blades for earthmoving, brushcutters and mulchers for vegetation management, cold planers and wheel saws for roadwork, compactors for soil preparation, and hydraulic hammers for breaking through concrete or rock. For material handling, options like bale grabs, bale spears, fork tines and carriages, material handling arms, and nursery forks deliver efficient load management. Snow-focused tools such as blowers, plows, pushes, and wings keep winter operations running smoothly, while stump grinders, tillers, trenchers, rakes, shears, and power box rakes expand the machine’s capabilities even further. Advanced “Smart” attachments, including the Smart Backhoe, Smart Dozer Blade with Assist, and Smart Grader Blade with Assist, bring intelligent control and precision grading technology directly to the operator’s fingertips.

To match the right hydraulic power with each job, the Cat 275 offers three auxiliary hydraulic performance levels: Standard Flow for general-purpose attachments, High Flow for applications requiring increased hydraulic output, and High Flow XPS for maximum flow and pressure when running the most demanding hydro-mechanical tools. An available Rear Auxiliary ready option further expands versatility by powering attachments mounted at the rear of the machine, such as winches or rear scarifiers. Together, these capabilities make the Cat 275 Compact Track Loader a high-performance tool carrier ready to take on virtually any task with efficiency and control.